McLAREN F1 ROAD CAR

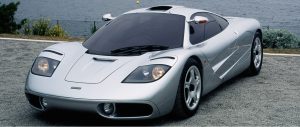

The philosophy behind the F1 road car was simple – to be the finest drivers’ car ever built, or ever likely to be built… This meant producing a car not only with outstanding performance but one versatile and usable as an everyday vehicle.

McLaren Cars was created in 1990 as a new British car company to be involved in leading edge car design using all of the experience and technology available to the McLaren Group. The company’s debut vehicle, the McLaren F1, was produced in 1994 and became the fastest-ever production road car when it achieved a world-record speed of 240mph/386kph.

In 1999 McLaren Cars entered into an agreement with DaimlerChrysler to design, develop and manufacture the Mercedes-Benz SLR McLaren super sports car. The SLR is being manufactured at the McLaren Technology Centre and was launched at the Frankfurt Motorshow in 2003

McLaren produced 106 McLaren F1s between 1992 and 1998.

Production of the McLaren F1 drew to a close in May 1998, with a total production of 100 cars, made up as follows:

- F1 – 64

- F1 LM – 5

- F1 GT – 3

- GTR 95 – 9

- GTR 96 – 9

- GTR 97 – 10

For the F1, it requires a few moments thought to come to terms with the fact that only 64 of these exquisite cars will ever exist. Their rarity is guaranteed, and consequently, their value is likely to increase with time.

Most of the existing owners intend to keep their cars for their lifetime – some even intend to pass them on to their own children. But ,just occasionally, an F1 becomes available through McLarens facilitation service, which helps to place existing F1’s with new owners

Having secured an F1, the new owner would then expect McLaren to rebuild the car to his own specification. This would include a seat fitting to ensure that all the controls are perfectly positioned, plus any combination of repainting, retrimming and options that he requires.

Described as ‘one of the greatest GT cars of all time’ the McLaren F1 GTR dominated GT racing from 1995 to 1997. A total of 28 F1 GTR race cars were built:

- 1995 F1 GTR – 9

- 1996 F1 GTR – 9

- 1997 F1 GTR – 10

The 1995 F1 GTR was designed and produced in just a few months in order to have cars ready for the new GT class. Only lightly modified from the F1 road car it confirmed the design integrity of the F1 by taking 1st, 3rd, 4th, 5th and 13th places at the Le Mans 24 hour race at the first attempt, as well as the Global GT Championship.

For 1997, although power was pegged at around 600 bhp, radical weight saving and significant increases in downforce meant that the cars were up to five seconds a lap faster. Despite starting from the lightweight F1 road car, small weight reductions had been made in both 1995 and 1996. However for 1997, a massive 85kg weight reduction was achieved, for a final weight of 915kg. The huge increase in downforce was achieved by using the longer nose and tail section from the F1 GT road car together with a much larger and more efficient rear wing. In what was to be its final year in front line GT racing, the F1 GTR achieved second place in the European Championship. However, the reliability of the car was demonstrated yet again at Le Mans, where the F1 won the GT category and secured 2nd place overall. McLaren continue to provide full spare part and technical support world-wide for these cars through their Customer Care department

FORMULA 1 TECHNOLOGY

The McLaren F1 benefits from World Championship Formula One technology and experience and is the world’s first production road car to feature an all carbon composite monocoque and body structure. This unique material combines the low weight necessary for performance with exceptional strength to exceed demanding industry safety requirements.

POWERTRAIN

McLaren Automotive commissioned the BMW S70/2 engine, designed and built specifically for the F1. This 6.1 litre, quad-cam, 48-valve V12 power unit produces no less than 627 bhp and drives through a bespoke six-speed transaxle gearbox.

RADICAL DESIGN FEATURES

- Central driving position

- Ground-Plane Shear’ suspension geometry

- Intelligent brake cooling

- Fan-assisted ground-effect aerodynamics

These and many more simply amplify the F1’s purity as the ultimate “drivers’ car”.

Each McLaren F1, tailor-made to the owners’ personal specification, featured as standard full air conditioning, a superb ultra lightweight CD stereo system and exclusive hand-made luggage in soft leather.

In March 1998, the F1 confirmed that it is the fastest production car in the world, achieving a record top speed of 240.14mph. This was a record it held until March 2005. This achievement was made all the more spectacular by the fact that the McLaren F1 was never conceived to achieve this record. It was merely a consequence of its unrivalled focus and supreme engineering as the ultimate drivers’ car.

McLAREN F1 ROAD CAR – PRODUCTION

Production of the McLaren F1 drew to a close in May 1998, with a total production of 100 cars built, sold and delivered to customers. Of the 100 cars 64 were F1 road cars, five were F1 LM versions built to commemorate victory at Le Mans in 1995 and three were F1 GT road going versions of the long tail 1997 F1 GTR race car. The remaining 28 were F1 GTR race cars built for private customers competing in the FIA GT series and the 24 Heures du Mans. (64) F1, (05) F1-LM, (03) F1-GT, (09) GTR-95, (09) GTR-96, (10) GTR-97

McLAREN F1 ROAD CAR – EQUIPMENT

- Full cabin air conditioning

- SeKurit electric defrost/ demist windscreen and side glass

- Electric window lifts

- Remote central locking

- Kenwood CD stereo system

- Cabin access release for opening panels

- Tailored document case

- Cabin stowage department

- Four lamp high performance headlight system

- Rear fog and reversing lights

- Courtesy lights in all compartments

- Map reading lights

- Remote battery charging point

- Facom titanium tool kit

- External battery charger

- McLaren F1 owner/drivers handbook

McLAREN F1 ROAD CAR – TRACK RECORD

The McLaren F1 set three incredible speed records on its way to making automotive history as the finest road car every produced. On March 31, 1998, the McLaren F1 obliterated the production road car world speed record in XP5, achieving a new official top speed of 240.1mph/386.7kph at Germany’s VW Ehra-Lessien proving ground. Incredibly this was a record the F1 held for 7 years, until March 2005. On December 16th 1998 the same McLaren F1, driven by Peter Taylor, an independent test and development engineer broke the high-speed circuit record at MIRA averaging 168mph round the 2.82 mile banked circuit with a maximum speed of 196.2mph. In March 1999 BBC’s Top Gear, in conjunction with McLaren Automotive, set a new UK closed circuit record in aid of the Comic Relief charity. Driven by Tiff Needell XP5 once again sensationally set the fastest lap record of a British circuit averaging 195.3mph round the 2-mile banked circuit at Millbrook Proving Ground in Bedfordshire.

McLAREN F1 ROAD CAR – SPECIFICATION

Performance

- Top Speed 386/240.1 km/h / mph

- 0-60 3.2 s

- 0-100 6.3 s

- 0-150 12.8 s

- 0-200 28 s

- 1/4 mile 11.1 s

@ 222 / 138 km/h / mph

Standing km 19.6 s

@ 285 / 177 km/h / mph

Powertrain

- Type Number S 70/2

- Cylinder Arrangement V12

- Cylinder Angle 60 degrees

- Power Output 461 / 627 kW / PS @ 7500 rpm

- Max. Torque 651 / 480 Nm / lb.ft @ 5600 rpm

- Engine Capacity 6064 / 369.9 cc / in 3 Valves/Cylinder 4

- Bore 86.0 / 3.38 mm / inches

- Stroke 87.0 / 3.42 mm / inches

- Compression Ratio 11.0:1

- Ignition system Transistorised system with twelve individual coils

- Induction system 12 single throttle valves, carbon composite airbox

- Valvetrain Chain driven double overhead camshaft with continuosly variable inlet valve timing.

- Engine Block Cast aluminium 60 deg V12

- Cylinder heads 4 valves per cylinder cast aluminium alloy

- Flywheel Aluminium

- Cam Carriers/Covers Cast magnesium

- Lubrication System Dry sump magnesium casting with scavenge pumps and one pressure pump

- Fuel 95-98 RON unleaded

- Oil 5W40/10W60

- Cooling System Twin aluminium water radiators and oil/water heat exchanger.

- Fuel system Flexible safety fuel cell with in-tank high pressure pump

- Electrics 12V system with high capacity battery & 160 amp alternator;Chassis ECU, Engine ECU, DC/DC converter for heated glass

- Transmission Transverse unit with high speed bevel gears and spur final drive

- All synchro constant mesh 6 Speed

- Limited slip differential

- Fan assisted air / oil radiator – pumped lubrication system

- 1st Gear Ratio 3.23/8.7

- 2nd Gear Ratio 2.19/12.7

- 3rd Gear Ratio 1.71/16.7

- 4th Gear Ratio 1.39/20.0

- 5th Gear Ratio 1.16/24.0

- 6th Gear Ratio 0.93/30.0

- Final Drive Ratio 2.37:1

- Clutch Triple plate Carbon/Carbon

- 200mm (7.87″) diameter

- Remote actuation (hydraulic)

- Steering Unassisted rack and pinion

- Two turns lock to lock

Chassis

- Front Suspension Double wishbones, Ground Plane shear Centre sub-frames, light alloy dampers/ co-axial coil springs, anti-roll bar

- Rear Suspension Double wishbones, inclined Axis Shear mounting system, light alloy dampers/ co-axial coil springs, toe-in / toe-out control links

- Front Tyre 235/45 ZR 17

- Front Wheel 9 x 17 inches

- Rear Tyre 315/45 ZR 17

- Rear Wheel 11.5 x 17 inches

- Front Calliper Type 4 pot monobloc light alloy calliper

- Rear Calliper Type 4 pot monobloc light alloy calliper

- Front Brake disc Type ventilated

- Rear Brake disc Type ventilated

- Front Brake Disc diameter 332 / 13.07 mm / inches

- Rear Brake Disc diameter 305 / 12 mm / inches

- Front Brake Disc Thickness 32 / 1.26 mm / inches

- Rear Brake Disc Thickness 26 / 1.02 mm / inches

- Turns Lock-to-Lock 2

- Parking Brake Automatic computerised control system

- Brake Cooling Automatic computerised control system

- Turning Circle 13 / 42.7 m / ft

Body

- Length 4287 / 168.78 mm / inches

- Width 1820 / 71.65 mm / inches

- Height 1140 / 44.88 mm / inches

- Wheelbase 2718 / 107.01 mm / inches

- Front Overhang 970 / 38.18 mm / inches

- Rear Overhang 599 / 23.58 mm / inches

- Front Track 1568 / 61.73 mm / inches

- Rear Track 1472 / 57.95 mm / inches

- Luggage Capacity – 2 occupants (VDA) 283 / 10 litres / cu ft.

- Luggage Capacity – 3 occupants (VDA) 227 / 8 litres / cu ft.

- Fuel Tank Capacity 90 litres

- Kerb Weight 1140 / 2513 kg / lbs

- Weight Distribution 41.2/58.8 F/R

- Drag Coefficient 0.32

- Aerodynamics Full underbody air management (fan assisted). Driver selectable high downforce mode. Automatic brake and balance aerofoil system.

TECHNICAL SPECIFICATION

DIMENSIONS

| Length | 4,288mm (168.8 inches) |

| Width | 1,820mm (71.6 inches) |

| Height | 1140mm (44.8 inches) |

| Ground clearance | 120mm (4.7 inches) |

| Wheelbase | 2718mm (107.0 inches) |

| Front track | 1568mm (61.7 inches) |

| Rear track | 1472mm (57.9 inches) |

| Dry weight | 1,018kg (2,244lbs) |

ENGINE

Type number S 70/2

Configuration V12

V-angle 60-degrees

Displacement 6,064cc (369.9 cubic inches)

Bore / Stroke 86.00mm (3.38 inches) / 87.00mm (3.42 inches)

Compression ratio 10.5:1

Ignition system Transistorized system with 12 individual coils

Induction system 12 single throttle valves, carbon fibre airbox

Valve train Chain-driven double overhead camshaft with continuously

variable inlet valve timing

Engine block Cast aluminium 60-degree V12

Cylinder heads 4 valves per cylinder, cast aluminium alloy

Flywheel Aluminium

Cam carriers / cover Cast magnesium

Exhaust emission control Four catalytic converters with ‘Lambda’ sensors, secondary air

injection

Alternator 160 amp

Lubrication system Dry sump, magnesium casting – with four scavenge pumps

and one pressure pump

Fuel 95-98 RON unleaded

Oil Shell TMO synthetic 5W40

Power Over 404 kilowatts (550 horsepower) @ 7,000rpm

Torque Over 600Nm between 4,000-7,000rpm

Maximum rpm 7,500

COOLING SYSTEMS

Twin aluminium water radiators and oil / water heat exchanger

FUEL SYSTEM

Safety fuel cell with in-tank high pressure pump

ELECTRICS

12 volt system with high capacity battery and 160 amp alternator

Chassis ECU

Engine ECU

DC / DC converter for heated glass

CHASSIS

| Front suspension | Double wishbones, GPSC subframes, light alloy dampers / co-axial coil-springs, anti-rollbar |

| Rear suspension | Double wishbones, ISA mounting system, light alloy dampers /co-axial coil-springs, toe-in / toe-out control links |

TRANSMISSION

Transverse unit with high speed bevel gears and spur final drive

All-synchro constant-mesh 6-speed

Limited slip final drive differential

Magnesium case

Air / oil radiator – pumped lubication system

CLUTCH

AP triple plate carbon / carbon: 200mm (7.87 inch) diameter

Remote actuation (hydraulic)

STEERING

Rack and pinion

Lock to lock 2.5 turns

Turning circle 12.6 metres (41 feet 4 inches)

WHEELS

Magnesium 431.8mm (17 inch) diameter

Front 228.6mm (9 inches) wide

Rear 292.1mm (11.5 inches) wide

Centre lock with retaining pin

TYRES

Front 235/45 ZR17

Rear 315/45 ZR17

BRAKES

| Front | 332mm (13.07 inches) diameter x 32mm (1.26 inches) thick ventilated disc, 4 pot monobloc light alloy caliper |

| Rear | 305mm (12.01 inches) diameter x 26mm (1.02 inches) thick ventilated disc, 4 pot monobloc light alloy caliper |

| Parking brake | rear, mechanical, light alloy caliper |

| Brake and Balance ‘Foil | Automatic – computerised control system |

| Brake cooling | Automatic – computerised control system |

CAPACITIES

| Oil tank | 6 litres (1.3 imperial gallon / 1.6 US gallon), aluminium construction |

| Fuel tank | 85 litres (18.75 imperial gallon / 22.4 US gallon), safety fuel tank |

| Luggage | 227 litres (8 cubic feet) – 3 occupants 283 litres (10 cubic feet) – 2 occupants |

F1 In Depth

The primary design consideration for the McLaren F1 has been to make it without reserve ‘a driver’s car’, an extremely high-performance design which advances all conventional boundaries. It combines Formula 1 racing car dynamics with genuine Grand Touring capabilities. ▪ Beginning with its radical and entirely innovative one-plus-two seating configuration, the McLaren F1 now applies several such advanced solutions to all the inherent shortcomings of conventional mid-engined sportscars. ▪ From conception to production, the F1 has never been just another extravagantly styled, highly specified and over-sized ‘head turner’. It has instead been created entirely as an exceptionally lightweight, compact, precise design of intrinsic purity and real practicality. ▪ Its centreline driving position provides optimum visibility, control, comfort and safety. Vitally – as in McLaren’s World Champion racing cars – driver and vehicle become as one. Both ‘rear-seat’ passengers are also located well inboard, in effect just behind the driver’s shoulders, in similar comfort and great safety. ▪ With such spacious accommodation for three tall adults, the McLaren F1 is plainly not ‘just another’ mid-engined supercar. It also applies equally fresh solutions to such vital areas as transmission, suspension and aerodynamic management. ▪ McLaren F1 owners will be joining an exclusive club – each car will be individually commissioned, custom built and tailored to its owner within the overall design’s distinctive engineering envelope. ▪ Each McLaren f1 will thus write an exclusive piece of automotive history, becoming a hand-made masterpiece embodying cutting-edge technology and precision-engineered to the same exacting standards as McLaren’s multiple World Championship-winning Grand prix cars. Every F1 owner will receive the attention which helped make Niki Lauda, Alain Prost, and Ayrton Senna multiple McLaren World Champions…

HISTORY OF McLAREN THE MARQUE WAS FOUNDED BY BRUCE McLAREN IN 1964 AND HAS SINCE PRODUCED THE MOST SUCCESSFUL GRAND PRIX CARS IN MOTOR RACING

HISTORY

While the McLaren F1 is the british marque’s first production road car, it already boasts a rich heritage… ▪ The McLaren marque was founded by driver/engineer Bruce McLaren in 1964 and in recent years McLaren International has produced the most successful Grand Prix cars in motor racing history. ▪ McLaren drivers Emerson Fittipaldi, James Hunt, Niki Lauda, Alain Prost and Ayrton Senna have all won the Formula 1 World Championship, including seven of the last eight series from 1984, while the marque has also accumulated seven Formula 1 Constructors’ titles. ▪ While McLaren is familiarity associated today with Formula 1, it has also achieved enormous success in sports car competition – particularly in the North American ‘Can-Am’ series, in which the McLaren works cars of Bruce himself and team-mates Denny Hulme and Peter Revson won five consecutive Championship titles from 1967-1971. ▪ Tragically, Bruce died in a Can-Am car testing accident at Goodwood in 1970, and with him went his contemporary dream of the ultimate Grand Touring car – the McLaren-Chevrolet M6GT. ▪ However, the foundations he had laid ensured not only his company’s survival, but also its progress to set new motor racing standards, which it continues to do today… ▪ Bruce McLaren grew up in Auckland, New Zealand, greatly influenced by his garage proprietor father who raced both motor-cycles and cars. Bruce’s first ‘real’ racing car was a 1929 ‘Ulster’ Austin Seven, which he and ‘Pop’ McLaren carefully prepared for local hill-climb competitions. ▪ Bruce won his class first time out and graduated via various Cooper racing cars to become in 1957-58 his country’s first ‘Driver to Europe’. He rapidly graduated to a Formula 1 Cooper works drive in 1959, teamed with their future double-World Champion Jack Brabham.

▪ He became the youngest-ever Grand Prix race winner, and subsequently founded ‘Bruce McLaren Motor Racing Ltd’ in partnership with Teddy Mayer and Tyler Alexander to build Tasman Championship-winning ‘Coopers’ in 1964. Their first sports-racing cars for what became Can-Am racing quickly followed. ▪ McLaren enjoyed immense success, most notably their unique consecutive quintet of Can-Am Championship titles. The marque also established itself in Formula 1 in 1966-67 and won its first Grand Prix races in 1968. Its M16 cars later won three Indianapolis 500-Miles speedway classics in the 1970s. ▪ McLaren’s first World Championship was won by Emerson Fittipaldi in 1974, followed in 1976 by James Hunt’s success. Hard times followed, but decline was arrested in 1980 by a merger between Team McLaren and the highly successful Project Four organisation headed by present McLaren International Managing Director Ron Dennis. ▪ Project Four developed the world’s first moulded carbon-composite racing car which emerged in 1981 as the McLaren P4/1. Driven by John Watson it scored the new McLaren International team’s maiden victory in the British Grand Prix. ▪ In 1983, in conjunction with TAG Group S.A., McLaren International commissioned Porsche to design and develop the TAG Turbo V6 Formula 1 engine. In 1984, it powered new MP4/2s for Niki Lauda and Alain Prost to 12 wins to secure the Constructors’ title, with Lauda taking the Drivers’ crown. ▪ Prost emphasised the team’s domination of Formula 1 by winning back-to-back Championship titles in 1985-86. ▪ Designer Gordon Murray joined TAG/McLaren as Technical Director in 1987 and, in Formula 1 partnership with Honda for 1988, drivers Prost and Ayrton Senna won an unprecedented 15 of the 16 Championship rounds. Ten more GP wins followed in 1989 with Prost taking a third Championship title, while in 1990-91 Senna achieved McLaren’s second consecutive Drivers’ Championship success. ▪ In 1989, the TAG/McLaren Group’s Directors decided to broaden its business base and also to deploy the Group’s vast experience and specialist facilities to exploit Formula 1 technology in a standard-setting road car. Gordon Murray was also seeking a fresh technical challenge and had dreamt for years of creating ‘the ultimate road car’. ▪ Enter the McLaren F1…

McLAREN TODAY

THE F1 WILL CONFIRM MCLAREN CARS’ ENTIRELY NEW STANDARDS OF BUILD QUALITY AND TECHNOLOGICAL INNOVATION FOR HIGH-PERFORMANCE ROAD CARS

McLaren Cars was formed in 1989 to create a unique high performance road car reflecting the McLaren International World Championship Formula 1 racing team’s record-shattering standards. From the new project’s inception, Technical Director Gordon Murray and Commercial Director Creighton Brown set about recruiting a multi-talented team with wide motor industry experience. ▪ Gordon Murray has been associated with cars which have won over 50 Grand Prix races and four World Championship titles, his exquisitely-integrated designs embodying such trend-setting innovations as pull- and push-rod suspensions, carbon brakes, and underbody aerodynamic skirts – plus such renowned lateral thinking as the Formula 1 ‘FanCar’ and lowering suspensions. He subsequently devised the ingenious refuelling-stop/tyre change tactic to achieve record race-winning average speeds in early ‘80s turbocharged Formula 1 racing. ▪ But he had also cherished a lifelong ambition to create the ‘ultimate’ road car. Eager for a fresh challenge away from the Formula 1 circuits, he jumped at the opportunity offered by McLaren Cars to head a design team dedicated to do just that – to realise that dream, in conjunction with Peter Stevens – one of the leading figures in the outstanding ‘new wave’ of British automotive stylists. ▪ The McLaren F1 now represents an entirely new beginning within the world of exclusive sports cars of exceptionally high performance, a vehicle whose design simply re-writes all existing standards by applying wide-ranging technical innovation and imaginative conceptual thinking. ▪ McLaren Cars’ three-year prototype programme was launched in January 1990, in a purpose-built pre-production facility neighbouring McLaren International’s racing headquarters in Woking, Surrey. ▪ When the first production F1 is completed late in 1993, it will confirm McLaren Cars’ new standards of build quality and technical innovation for ultra-high performance road cars.

DESIGN CONCEPT

MASS IS THE ESSENTIAL ENEMY OF DYNAMIC PERFORMANCE IN ANY ‘SUPERCAR’. THERE IS NO SUBSTITUTE FOR LIGHT WEIGHT

The McLaren F1’s design is Formula 1-inspired throughout, yet freed entirely of racing’s regulation strait-jacket. This newfound freedom has unleashed all McLaren Cars’ ingenuity and imagination to perfect numerous frontier-advancing ideas within the F1. ▪ The objective has been simply to build, not only the finest high-performance sports car ever made, but also ever likely to be made. ▪ The McLaren F1 simply redefines such familiar, and often devalued terms as ‘sports car’, ‘Grand Touring car’ and ‘supercar’. It retains the finest virtues associated with each, offering fast and comfortable long-distance touring. ▪ The F1’s forward, centreline driving position and its uncompromisingly ‘driver centric’ cockpit ergonomics reflect pure Grand Prix practise. Their sole objective is to provide maximum visual and dynamic input to ensure instant obedience to driver command. ▪ Its aerodynamic form and features derive directly from Formula 1 technology – light years ahead of any applied by mainstream road car manufacturers. ▪ The full underbody ground-effect aerodynamic management system is further enhanced by fan-assisted removal of ‘boundary layer’ airflow. Further advanced features include active intelligent brake cooling and – crucially – automatic aerodynamic Centre of Pressure control. ▪ Innovative front and rear suspension designs resolve age-old incompatibilities between precision handling and quiet, compliant comfort in a high-performance road car. ▪ The F1 employs conventional Formula 1-style mid-engine mounting – a configuration ideal to combine optimum weight distribution and mass concentration within the wheelbase. Most mid-engined sports car designs compromise such conceptual purity with badly placed luggage, fuel or driver load, or by towering engine/transmission assemblies raising Centre of Gravity height. ▪ Now the McLaren F1 – for the first time in any sports car – avoids all such compromise. ▪ By ingenious packaging it concentrates all its engine/gearbox, fuel, occupant and luggage masses closely around its Centre of Gravity – which is maintained at minimum height and remains static under all load conditions.

▪ The F1’s exceptionally low polar moment of inertia guarantees nimble handling and manoeuvrability. Above all, the McLaren f1 has the highest power-to-weight ratio of any production car yet made. ▪ Mass is the essential enemy of dynamic performance in any ‘supercar’ – there is no substitute for light weight. The F1’s mere 1,018kg (just 2,244lbs) includes the most powerful and efficient purpose-designed large capacity V12 engine ever applied in production. Coupled with a production car chassis designed to be more rigid than any previously conceived – the result is dynamic indeed. ▪ The F1’s incredibly low target weight has been achieved despite meeting exceptionally demanding requirements for strength, stiffness, safety and comfort. Only the most advanced carbon composite structures, the most penetrating design and ingenious conceptual thinking could reconcile these apparently conflicting requirements. The result is the world’s first full advanced-composite production car – a car whose revolutionary features simply re-write the rules. ▪ This is the standard-setting McLaren F1…

CHASSIS AND STRUCTURE

THE McLAREN F1 IS DESIGNED FOR GREATER TORSIONAL AND BENDING STIFFNESS THAN ANY OTHER PRODUCTION CAR EVER BUILT

The McLaren F1’s advanced-composites monocoque comprises the entire chassis/body unit, combining both uni-directional and woven carbon fibre materials. Most primary structure panels are double-skinned and stiffened by aluminium honeycomb. The McLaren f1 possesses immense torsional and bending stiffness. ▪ The primary structure was designed and developed using a computer aided design finite element analysis programme to optimise both material thickness and fibre orientation for maximum strength, stiffness and safety – sophistication impossible with traditional chassis materials. ▪ The monocoque’s primary strength derives from two longitudinal large-section floor beams, uniting lateral cockpit bulkheads. Behind the driver’s seat, a sturdy pier rises integrally with the engine air-box to provide exceptional roll-over protection, integrated into the roof and A- and B-pillars, to form an enormously strong ‘survival cell’. This is augmented by a tailor-made driver restraint harness and laminated fixed cabin glass throughout. ▪ Front and rear crash structures – composite forward mouldings and the Inconel rear silencer box – far exceed all legal requirements worldwide. The Formula 1 specification puncture-proof fuel cell is also safely centre-mounted. ▪ The engine doubles as a load-bearing chassis member, mounted against the tear cockpit bulkhead and attached to two monocoque shoulder beams at the rear. ▪ In each front engine mounting, intricately tailored semi-flexible bushes rigidly transmit traction and braking loads, while absorbing vibration and noise. All major torsional loads from the rear suspension are similarly absorbed via flexible bushes uniting each cylinder head to the shoulder beams. ▪ The totally-integrated carbon structure has been created entirely within McLaren cars’ own advanced composites facility, incorporating materials and techniques at the forefront of this technology – several of them unique in road vehicle manufacture.

THE CHASSIS

FOR THE PRIMARY STRUCTURE OF McLAREN’S FIRSTPRODUCTION SPORTS CAR, NO MATERIAL OTHER THANCARBON COMPOSITE WAS EVER CONSIDERED

The McLaren F1 achieves its astonishingly lean target weight of only 1,018kg (2,244lbs) thanks largely to its moulded advanced carbon-composite monocoque chassis/body structure. ▪ In fact, it was McLaren International who pioneered modern automotive moulded carbon-composite chassis technology in 1981 with its race-winning Type MP4/1 Formula 1 design. ▪ Carbon fibre simply offers an immense stiffness-to-weight ratio, hence its use in chassis construction of every significant racing car built today. ▪ The contrast in technology between Formula 1 and everyday car production is starkly demonstrated by the fact that some major manufacturers are only now beginning to consider aluminium chassis structures over steel, whereas leading Formula 1 designers abandoned steel for aluminium thirty years ago. It is over 10 years now since McLaren International led the way in rejecting aluminium in favour of advanced composite construction. ▪ For McLaren’s first production sports car, therefore, nothing other than carbon composite was ever considered. ▪ The F1’s styling reflects the structural freedom offered by McLaren Cars’ advanced composite moulding techniques, and combines purely functional aerodynamic form with aesthetic appeal. ▪ The F1 incorporates dramatic aerodynamic design derived from long experience of Formula 1 frontier technology. It is the first production car to be developed aerodynamically by an expert team of Formula 1 aerodynamicists employing the latest in moving-ground wind tunnel technology. ▪ Formula 1 engineering typically unites multiple disciplines in singular components, combining light weight with strength, form with function. This same engineering ethic is now embodied within the McLaren F1.

SUSPENSION AND STEERING

THIS RADICAL NEW SYSTEM OFFERS A HITHERTOIMPOSSIBLE COMBINATION OF COMPLIANT FREEDOM YETPRECISE GEOMETRIC CONTROL

The McLaren F1’s suspension will offer a remarkable breakthrough in compliant ride comfort without compromising Formula 1-standard geometry control. ▪ Since the rigid suspension mountings necessary in racing would transmit unacceptable shock, vibration and noise in a road car, adequate compliance and truly controlled geometry have until now been mutually incompatible. ▪ Now McLaren Cars’ ‘Ground-Plane Shear Centre’ (or ‘GPSC’) front suspension-mounting system offers a solution to this age-old problem. The front suspension features unequal-length double wishbones supporting a machine cast-aluminium hub carrier. Each front suspension wishbone is connected to a subframe via plain bearings, the frame itself being four-point mounted upon the carbon monocoque via purpose-designed elastomeric bushes. ▪ This radical new system offers a hitherto impossible combination of compliant freedom yet precise geometric control, presenting in principle a tyre contact patch stiffness three times greater than that at the hub centre, compared to a conventionally compliant system’s stiffness of one-third that at the hub. ▪ Thus ‘GPSC’ preserves maximum ‘feel’ for the F1 driver, while still insulating its passengers from road shock. ▪ Above all, ‘GPSC’ exhibits four major Formula 1 attributes; it is elegant, simple, light and it works. ▪ Optimum steering precision is achieved by housing its rack directly within the cast front bulkhead for maximum rigidity. It requires no power assistance. ▪ Because the car’s rear end is powered, ‘GPSC’ is inappropriate there, but despite a different approach in detail, the innovative solutions adopted are equally significant, achieving minuscule deviation from the theoretical designed geometry even under the most extreme braking, cornering and tractive inputs. ▪ Rear suspension loadings are all fed via the transaxle and engine assembly into the central monocoque chassis, drive and braking loads being accepted via axially rigid bulkhead mountings. Torsional loads are absorbed via innovative new ‘Inclined Shear Axis’ – ‘ISA’ – mounts into the shoulder beams each side of the engine. ▪ All mounting bushes also act as high-effective noise and vibration insulators, while the V12 engine’s substantial mass is employed as a vibration damper to absorb high-frequency road shock transmitted via the F1’s exceptionally precise rear suspension geometry. ▪ The F1’s lower-wishbone rear mounts are linked laterally by a compliant beam, flexibly mounted on the transaxle casing to permit asymmetrical displacement of either wheel, but rigid resistance to symmetrical loadings. ▪ McLaren Cars have selected Bilstein to design and develop the F1’s special lightweight monotube gas-pressurised dampers. These race-derived units are manufactured from aluminium to give 30 percent greater heat dissipation and are accurately tuned and adjusted to suit the F1’s characteristics.

BRAKING SYSTEMS

IMPECCABLE BRAKING IS A PRIMARY FORMULA 1REQUIREMENT IN EQUAL DEMAND ON THE ROAD.BRAKING PERFORMANCE IS THUS A MAJOR PRIORITY

In development of the F1, McLaren Cars have worked closely with Brembo of Italy to develop exceptionally high-performance brakes using – for the very first time on a production car – Formula 1-type ‘monobloc’ aluminium four-piston callipers, clasping the latest road-usable ventilated discs. Fully divided front and rear hydraulic circuits are actuated by the Formula 1-style floor-pivoted pedal, while the F1’s lightweight aluminium handbrake calliper has also been specially developed by Brembo. ▪ Slowing such a car safely and efficiently from near maximum speeds demands considerable brake cooling. Normally, such a high-speed cooling requirement becomes embarrassing at low and medium speeds, reducing disc, calliper and pad base temperature excessively between applications. Consequently, the McLaren F1 now introduces ‘intelligent’ brake cooling. ▪ With speed and brake application sensors feeding an electronic control unit, brake-cooling air intake ducts open automatically only when the driver makes a sufficiently-demanding application. Since closed brake ducts create no drag, they improve the F1’s aerodynamic efficiency. Furthermore, the system enhances braking ‘feel’ for the driver by sustaining comfortable pad and disc base temperatures during enthusiastic motoring. ▪ In contrast, two conventional areas of modern road car development which actually degrade driver feel and feedback are power brake assistance and anti-lock braking systems – ABS. ▪ By developing the F1’s brakes along Formula 1 lines, and particularly by achieving the project’s exceptionally low target weight, power assistance is unnecessary. With the automatic aerodynamic Brake and Balance ‘Foil feature – see page 20 – braking effect and driver feel are improved, since its downforce enhancement then assists the driver under heavy braking by increasing the load on each wheel. ▪ Further evidence of how – in the McLaren F1 – Grand Prix racing really does ‘Improve the Breed’.

WHEELS AND TYRES

RIGHT FROM THE McLAREN F1’S INITIAL DESIGN,THE TYRE WAS CONSIDERED AS AN INTRINSICSUSPENSION ELEMENT

Potential speeds above 200mph, over 550bhp, high cornering loads and high downforce demand no ordinary tyres. McLaren and Goodyear first raced together in 1968 and now cooperate on the McLaren F1 programme. ▪ The dedicated Goodyear ‘F1’ P235/45ZR17 front, and P315/45ZR17 rear, tyres have been created using the latest race-proved techniques – computer modelling, CAD/CAM generated mould cavities, high-speed constructions, and exotic lightweight materials. ▪ Right from the McLaren F1’s initial design, the tyre was considered as an intrinsic suspension element within the programme’s complex handling and comfort calculations. Weight, safety, noise and dynamic performance were all vital factors. ▪ Chosen tread pattern is asymmetric and directional, sharing many of Goodyear’s patented ‘Quattro Stazione’ pattern features from their latest racing rain tyre. Tyre sizes have been carefully selected to optimise traction and braking, while fostering the finely balanced handling which McLaren Cars demands. A current trend towards ever-larger wheel diameters has been resisted, 17-inch being judged best for weight, package and contact patch geometry. ▪ Since the tyres are different-sized front and rear and directional, no two on the F1 are the same. Consequently, the F1 carries no spare, the weight of a component which is most unlikely to fail in normal use being deemed unacceptable. However, in case of emergency a puncture sealant aerosol is carried. ▪ Because the ‘F1’ tyre is uniquely tailored for this exclusive design, it will be manufactured using Formula 1 techniques in Goodyear’s race tyre plant at Akron, Ohio, USA. ▪ The McLaren F1 rides on purpose-designed OZ Racing wheels, painstakingly developed to match the car’s character. They are cast like Formula 1 racing wheels in aerospace-grade magnesium alloy, and feature sophisticated anti-corrosion measures to ensure sustained performance and appearance throughout the McLaren F1’s long predicted service life.

STYLING

ACCESS TO THE CENTRELINE DRIVING SEAT IS ASSURED BY WIDE-OPENING ‘DIHEDRAL DOORS’ INCORPORATING SECTIONS BOTH OF FLOOR AND ROOF

McLaren F1 size, style and aerodynamic targets were established upon the project’s inception, while Gordon Murray has harboured its one-plus-two seating concept since the 1960s. ▪ Peter Stevens headed McLaren Cars’ styling studio, working with the wind tunnel team to produce hundreds of drawings and many models preceding the full-size ‘clay’. Thousands more man hours then perfected the F1’s final shape. ▪ Its external envelope is tailored to optimum aerodynamic performance, the sophisticated ground-effect solution obviating conventional drag-inducing spoilers and wings. ▪ The F1 requires no tail overhang to house projecting mechanical components or after-thought luggage space. These are packaged within its wheelbase, as are all major masses to minimise polar moment of inertia – and maximise inherent agility. ▪ The F1’s nose form is far removed from the conventional deep ‘chin spoiler’. On each side, lightweight aluminium radiators are located within profiled air-ducts. Cooling air exits into the low pressure area behind each wheel arch. Between its twin air intakes, the F1’s nose swoops upward, directing airflow beneath the floor, which rises under the tail to form a downforce-generating ‘diffuser’ whose exit arches provide the only visible clue to the ground-effect aerodynamic design. ▪ A scuttle-top air deflector ‘foil deflects raindrops and insects from the windscreen, while vents behind the headlights assist cooling when idling stationary in traffic. A discreet high-efficiency overhead intake feeds cool air to the V12 engine. ▪ Easy access to the centreline driving seat is assured by wide-opening ‘Dihedral Doors’ incorporating sections both of floor and roof, which open in an innovative, space-saving manner. ▪ The moulded rear windscreens provide an unobstructed view of the 48-valve V12 engine and a laminated transparent soundscreen separates engine bay from cockpit. ▪ The tail deck is extensively louvred to release hot air from the engine and exhaust bay. Its trailing edge also houses the unique ‘Brake and Balance ‘Foil’, a crucial feature of the McLaren F1’s aerodynamic systems.

AERODYNAMIC CONCEPT

ONLY SUCH SOPHISTICATED WIND TUNNELS CAN MIMICTHE COMPLEX INTER-ACTION BETWEEN A MOVING CARAND THE ROAD SURFACE UPON WHICH IT RUNS

The McLaren F1’s dramatic aerodynamic features are derived from McLaren International’s long experience of trend-setting research in Formula 1. The f1 is thus the first production car to benefit from first-hand design by a fully experienced team of Formula 1-trained aerodynamicists utilising the latest in moving-ground wind tunnels. ▪ While most existing production cars are tested in fixed-floor tunnels in which the test-car’s wheels are stationary, every Formula 1 racing car designer knows that modern moving-ground wind tunnels provide the only accurate representation of actual-car aerodynamic behaviour. The McLaren F1 project has been developed, analysed and fine-tuned in the same moving-ground wind tunnel facility in Teddington, England, in which McLaren International’s World Championship-winning Formula 1 cars have been perfected. Only such sophisticated wind tunnels can mimic the complex aerodynamic inter-action between a moving car and the road surface upon which it runs. ▪ Painstakingly-faithful 30 percent full-size models of projected F1 forms have been investigated within an airstream velocity of 44 metres per second. Balance forces generated within the model have been recorded and analysed from 70-point Scanivalve sensing. Ultra-violet paint streamlining and flow visualisation have been employed in one of the most comprehensive wind tunnel analyses ever applied to a production road car design programme.

GROUND EFFECT

BY DIRECTING AIRFLOW BENEATH THE WORKINGUNDERFLOOR, AIRSTREAM IS HARNESSED TO GENERATEPOWERFUL, STABILISING DOWNFORCE

The McLaren F1 is the world’s first production car to feature full ground-effect aerodynamics with fan assistance. ▪ By careful management of airflow between the McLaren F1’s underfloor and the moving road surface beneath, powerful aerodynamic forces can be harnessed – as in Formula 1 – for the driver’s benefit. ▪ Management of this airflow regime has come to be known as a ‘ground-effect’ aerodynamic system. ▪ Airflow beneath the car is compressed against the underlying roadway and then released through an expanding-section exit channel at the car’s tail – the curving underfloor surface of which is known as the ‘diffuser’. As airflow velocity has been accelerated through this underfloor ‘venturi’ system, so the pressure within it falls, and this low pressure area may then be harnessed as ‘downforce’ to suck the moving car bodily down against the roadway. ▪ In 1978 Gordon Murray stunned the Formula 1 racing world by creating the Swedish Grand Prix-winning Brabham BT46B ‘Fan Car’ driven by Niki Lauda, which generated massive aerodynamic downforce in part by fan assistance. Formula 1 rules were quickly altered to dismiss such devices! ▪ Now, with the McLaren F1 project governed only by comparatively liberal international road-car regulations, that ‘Fan Car’ theme is to some extent being re-introduced. ▪ A complex three-part rear diffuser beneath the F1’s tail incorporates a central single surface and two reflex shapes each side generate sufficient downforce to overcome the car’s natural aerodynamic lift. ▪ Simultaneously, two powerful electric fans remove boundary layer air from the rolled S-wave of ‘reflex’ diffuser sections, helping to control movement of the Centre of Pressure – the truly significant aerodynamic factor affecting vehicle stability and handling.

CENTRE OF PRESSURE CONTROL

THE ONLY SURFACE-BREAKING AERODYNAMIC DEVICE ISTHE NEAT ‘BRAKE AND BALANCE ‘FOIL TO MAINTAIN THE CENTRE OF PRESSURE IN THE REQUIRED LOCATION

At high speed, aerodynamic lift can compromise any car’s stability. Many high-performance sportscars carry wings to cancel this lift, but Formula 1 experience proves them inefficient and drag inducing. ▪ Major manufacturers often claim minimal drag coefficients – Cd – for new car shapes. Yet alone such figures are irrelevant. ▪ One crucial factor is aerodynamic Centre of Pressure – CoP – through which lift and downforce react upon the moving car. its location is vital to car behavious, yet amongst production sports and supercar designs, few address CoP control. ▪ Under maximum braking, weight transfer causes nose-down dive. Aerodynamically this attitude rushes effective CoP far forward, maximising front wheel load, minimising rear. The braking vehicle’s rear end is inevitably destabilised. ▪ On the McLaren F1, the only surface-breaking aerodynamic device is its neat ‘Brake and Balance ‘Foil’ hinged into the tail deck. Activated automatically by electronic control sensing heavy braking, this BB ‘Foil deploys at 30-degrees, slightly raising Cd, but crucially enhancing base-suction at the rear of the car to generate greater downforce from the underbody with its Centre of Pressure in the correct location. ▪ Thus braking stability is greatly enhaced by moving the CoP rearwards when conventional design would allow it to rush far forwards… ▪ Deploying this BB ‘Foil exposes rear-brake cooling intakes to control the extra heat being generated by the brake application. ▪ BB ‘Foil operation is an entirely different principle to anti-lock braking which maintains tyre adhesion by releasing application on imminent lock. ▪ The McLaren F1’s new system instead evenly increases tyre load during braking to postpone the onset of wheel locking. ▪ The F1 driver may also partially deploy its BB ‘Foil in a ‘High Downforce’ mode. Unlike a traction-limiting control device this actually increases grip and traction – another of the McLaren F1’s valuable safety options…

ENGINE AND TRANSMISSION

EVERYWHERE IN THIS MADE-TO-ORDER 6.1-LIRE V12MASTERPIECE ONE FINDS YET FURTHER EVIDENCE OFSIMPLE DEDICATION TO EXCELLENCE

Design purity is an intrinsic part of the McLaren F1. From the project’s inception, it was decided to utilise both a purpose-designed transmission and a high-performance 12-cylinder naturally-aspirated engine of great efficiency, all integrated from the beginning into the overall F1 package. While offering great power, the engine also had to meet worldwide emission and ‘green’ requirements since the McLaren F1’s concept combines ultra-modern technology with the most noble Grand Touring car values. ▪ The resultant naturally-aspirated V12 engine for the McLaren F1 has been purpose-built by BMW Motorsport in Munic, Germany, to meet all these demands. Commissioned by McLaren Cars, BMW Motorsport’s design and development team has been led by their universally acclaimed senior engineer Dipl. Ing.Paul Rosche. ▪ The McLaren F1’s 6.1-litre 60-degree V12 engine is an entirely new four-cam, 48-valve unit of extraordinarily compact design, sharing nothing with BMW’s unrelated smaller-capacity production-line V12. ▪ Paul Rosche and his BMW Motorsport engineers have a long association with both Ron Dennis of McLaren International and Gordon Murray of McLaren Cars. As early as 1974, BMW Motorsport supplied 2-litre 4-cylinder engines to Ron Dennis’ contemporary ‘Project Four’ European Formula 2 Championship team, and in 1978-79 Project Four built BMW M1 ‘Procar’ Coupes for the Grand Prix-supporting series won by Niki Lauda. ▪ BMW Motorsport entered Formula 1 with Brabham, producing 1.5-litre turbocharged 4-cylinder engines which powered driver Nelson Piquet in the Gordon Murray-designed Brabham-BMWs to World Championship titles in 1984-85 and 1988-91 with Shell fuels and lubricants playing a vital role. Now the ‘S70/2’ V12 engine and the ingenious transmission through which it drives have both been developed and perfected with Shell’s input and collaboration. From these old-established relationships of mutual respect the McLaren F1 has grown…

ENGINE

THE F1’S ENGINE PRODUCES ONE OF THE HIGHESTSPECIFIC OUTPUTS FOR A LARGE-CAPCITY NATURALLY-ASPIRATED UNIT IN PRODUCTION SPORTS CAR HISTORY

The BMW Motorsport ‘S70/2’ V12 engine for the McLaren F1 is a unique design, individually hand-assembled and dyno-tested for each owner to produce one of the highest specific outputs for a large capacity naturally-aspirated engine in production sports car history. ▪ Seeking performance with clean emission, the engine possesses extremely efficient heads, continuous variable inlet valve timing and an emission-control system incorporating secondary air supply and four catalytic converters with ‘Lambda’ exhaust gas analysis control. ▪ This 4-cam, 48-valve, 60-degree V12 engine’s 86mm bore and 87mm stroke displace 6,064cc. Compression ratio is 10.5:1 and with its chain-driven DOHC valvegear and TAG Electronic Systems fuel injection and engine management, power output is over 550bhp (404kW) at 7,500rpm, coupled to a peak torque in excess of 600Nm between 4,000 and 7,000rpm, with no less than 350Nm at only 1,500rpm! ▪ The load-bearing lightweight cylinder block is cast in aluminium-alloy with Nakasil coating. BMW Motorsport’s renowned engine weight- and size-reducing technology has paid handsome packaging dividends. In fact, this 6.1-litre V12 is little larger than current 3.5-litre Formula 1 racing engines. ▪ Lightweight magnesium-alloy castings provide the sump, oil-pump and variable valve-timing housings, cam-carriers and cam-covers. The airbox is made of carbon composite, while the voluminous exhaust catalysor system is cased in super-thin, ultra-high temperature resistant ‘Inconel’ sheet just 0.8mm thick and doubling as the F1’s rear crash structure. Dry-sump lubrication ensures adequate flow under high cornering loads and minimises Centre of Gravity height. Cooling is handled by individual water pumps to each cylinder bank. Everywhere within this tailor-made v12 masterpiece from Munich one can find further evidence of the McLaren F1’s purest design principle – total dedication to excellence.

TRANSMISSION

GEAR RATIOS OFFER AN ULTRA-CLOSE5-SPEED CLUSTER FOR 0-160MPH, PLUS A 6TH-SPEED200MPH-PLUS CAPABILITY

Wheelbase length in most mid-engined sports car designs is increased by conventional clutch and final-drive arrangements forcing the drive-output centre rearwards. Until now, all attempts to minimise wheelbase length – such as sitting gearbox and final-drive beneath the engine – have compromised handling, weight or efficiency. ▪ In conjunction with Traction Products Inc., McLaren Cars has imaginatively solved such problems, with the McLaren F1’s final-drive gear offset alongside its clutch, absolutely minimising engine/drive output centreline separation. ▪ This layout within a transverse-shaft gearbox – already inherently short front-to-rear – provides an exceptionally compact assembly within an extremely rigid cast magnesium casing accepting major rear suspension loadings. ▪ The F1 is also the first production car to adopt current Formula 1 practise by featuring a 200mm diameter aluminium flywheel and carbon clutch assembly. Their extremely low mass and inertia greatly enhance engine response and efficiency, and also save weight. ▪ The 6-speed gearbox has a full synchromesh gearchange with helical gears for optimum strength, quiet high-speed running and quick and efficient gear-changing. ▪ Further features include a sophisticated lubrication system, a remote clutch-operating mechanism tailored to provide optimum pedal weight and action, and an integrated purpose-designed starter system. ▪ Gear ratios offer a close 5-speed cluster for 0-160mph (257km/h) plus a 6th-speed presenting a comfortable, peaceful and long-striding 33mph (53km/h) per 1,000rpm cruising gear – plus top speed capability well over 200mph (321km/h) . ▪ The final-drive assembly also features a limited-slip differential, while purpose-made constant-velocity jointed high grade alloy-steel drive-shafts are used. ▪ As in all areas of the McLaren F1, exhaustive research and development effort has been applied to no-compromise design and manufacturing quality.

ELECTRONICS

TECHNOLOGY IS EMPLOYED WHICH HA SBEEN STRICTLYCONFINED UNTIL NOW TO THE HIGHEST LEVELS OFFORMULA 1 AND SPORTS CAR RACING

Close collaboration between McLaren Cars and their sister company in the TAG/McLaren Group – TAG Electronic Systems – has provided the F1’s highly innovative and sophisticated engine and chassis control features. ▪ TAG Electronic Systems offer a level of electronics expertise unparalleled within the motor industry, and is responsible for the electrical system on the F1. Throughout the F1, technology is employed which has been strictly confined until now to the highest levels of World Championship Formula 1 and sports car racing. ▪ The Engine Management System – EMS – combines the technology TAG has applied in Formula 1 and Group C management systems with the stringent extra demands of road-going emission control. Its computing is approximately ten times that of a mass-market equivalent. ▪ It provides individual ignition timing and fuelling control for every pulse on each cylinder and also manages the engine’s variable valve timing. Its software ‘algorithms’ which calculate ignition timings and fuel quantity consider such diverse factors as the rate of throttle movement and ambient atmospheric conditions. Split-second calculations are repeated on every firing cycle to ensure the most instantaneous information is acted upon. ▪ Further software algorithms monitor conditions within th inlet manifolds, commanding precisely calculated mixture enrichment or leaning-out during rapid throttle variations to provide genuine Formula 1-style engine response. ▪ The EMS employs feedback from four oxygen sensors to ensure the fuel/air ratio never exceeds the optimum working range of the exhaust-cleaning catalytic converters. Hence, even the world’s most stringent emissions requirements are complied with. ▪ An additional EMS function is to monitor engine use, logging temperature extremes, peak revolutions reached, high loads when not properly warmed through and myriad other details of the V12’s operational life. This engine logging can then be accessed during normal servicing to identify cause and effect. ▪ A second electronics unit, the Car Equipment Controller – CEC – manages everything from the electrically-heated cockpit glass to the brake cooling-duct flaps. Glass de-icing load can soar as high as 1,000 Watts, handled by a TAG-designed DC/DC converter. The CEC also monitors battery state and alternator charging and regulates glass heating load to suit. ▪ Brake-cooling flap control is derived from road speed and brake-line pressure sensors. The aerodynamic BB ‘Foil is also CEC controlled, via cockpit command when high downforce mode is selected, although brake cooling demands automatically over-ride as required. ▪ The CEC also supplies data to the instrument panel, manages the F1’s anti-theft system, checks all lamps, controls the courtesy lights and decides when to switch on the engine-bay cooling fans. It monitors all electrical system functions and checks safety conditions, for example braking the window lifts should they become obstructed. It also prevents the windows from being opened above 130mph (209km/h) . ▪ Both CEC and EMS systems constantly monitor both themselves and all functioning of the F1’s other electrical systems. If a fault should be detected, the CEC can signal the driver via the instrument panel display, indicating both the fault and its severity. ▪ In servicing, both EMS and CEC can communicate with the standard BMW computerised service tester, but a second more unusual facility is also featured. ▪ A modem telephone link is fitted in the car, permitting direct downloading of information to McLaren Cars. Diagnostic circuits within the EMS and CEC then identify faulty components and transmit the information direct for assistance. ▪ It is unlikely, however, that this modem telephone link would be required other than to verify that all is well. TAG Electronics Systems’ EMS and CEC units for the F1 embody all the hard-won lessons of Formula 1 experience. They are built to the most exacting standards, and every unit undergoes extensive testing prior to installation in the F1.

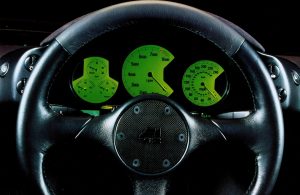

ERGONOMICS

PROBABLY MORE DESIGN EFFORTHAS BEEN INVESTEDIN THE F1’S ERGONOMICS AND CONTROLS THAN IN ANY OTHER AREA

In the F1, McLaren Cars has thrown away the rule book, and begun anew to avoid perennial supercar problems… Probably more deign effort has been invested in the F1’s ergonomics and controls than in any other area. In a Formula 1 Grand Prix car, the driver must be placed in absolute control. ▪ The F1 design team has worked unremittingly to site every primary and secondary control in precisely its proper place. ▪ One powerful tenet of F1 design has been to overcome many of the old-established layout problems usually affecting mid-engined road cars. ▪ These often result in offset primary controls which are forced towards the cabin centreline by front wheel-arch intrusions. There is an awkward compromise between turning circle – indicating front-wheel steering lock – and driver pedal space. ▪ The F1’s one-plus-two seating configuration avoids any such compromise. Its centreline driving position offers a spacious footbox with perfectly aligned pedals tailored to each individual owner’s preference. A lightweight carbon-composite seat finished in padded Connolly hide is moulded and tailored in Formula 1 style to each owner’s form. ▪ Much design time has been devoted to centre-drive support. Visibility is outstanding. Even the grip shape of the specially-made Nardi F1 steering wheel involved many hours of research, design and development. Steering is weighted for the driver. Nothing is allowed to mask steering ‘feel’. A minimal Formula 1-style dash panel in carbon composite presents clear specially-made analogue instrumentation, plus a liquid crystal computer read-out screen. ▪ Hand controls include finger-tip flipper switches behind the steering wheel boss, and an intricately crafted right-hand manual gearchange. ▪ Passenger space and comfort have not been forgotten. The McLaren F1 can accommodate two 95 percentile adult passengers – an industry standard indicating that only 5 percent of the population will be taller – in secure, safe and air-conditioned repose – providing yet another feature unmatched by any other supercar.

INTERIOR

IN AN INTENTIONAL RETURN TO 1930S’ PRESTIGE CAR PRACTISE, EACH MCLAREN F1 WILL HAVE BEEN DETAIL-FINISHED TO ITS NEW OWNERS’ REQUIREMENTS

In an intentional return to 1930s’ prestige car practise, each McLaren F1 can be detail-finished to the owner’s requirements. ▪ The F1’s interior is hand-crafted in Connolly Soft Assisted Aniline leather employing the very finest selected hides available. This material offers all the necessary qualities of a typical car interior leather – durable, light-fast, heat stable and consistent in texture – yet it is specially treated to provide superb flexibility, sensuous feel and even deeper texture. Connolly Leather’s policy of continuing research and development has ensured that nature’s traditional products are now even more beautiful and refined than ever before. ▪ The driving seat will have been hand-built and individually shaped and trimmed in the manner the McLaren International Formula One racing team applies for its Grand Prix drivers. Similarly, the steering wheel position will have been set-up and the foot pedals specially built, shaped and tailored to assure the finest possible ergonomic match. ▪ The occupants must be comfortable, they must be cool. Full air-conditioning is standard in the F1 with separate airflow ducting for driver and passengers. Side window drop-sections are electrically powered, while door locking is achieved by remote control. ▪ Secondary controls and switches have all been specially-designed, each finely engraved for identification. ▪ McLaren Cars has also developed an instrument panel combining exquisitely-made analogue dials with a high-technology read-out screen and information system. A defined ignition sequence is displayed on the dash panel instrument screen when the driver initiates the start procedure. ▪ On the switch panel beside the driver’s right hand, a flick-up trigger shield exposes the neat red starter button beneath. ▪ Press that button – and 6.1-litres of ultra-modern V12 will fire into life behind the McLaren F1 driver’s shoulders.

EQUIPMENT

FUNCTIONAL YET SUPREMELY DRIVEABLE, THE MCLARENF1 IS INTENDED ABOVE ALL ELSE TO BE USED…

The McLaren F1 can house a full 8 cubic feet (227 litres) volume of luggage in two cool, clean side compartments just ahead of its rear-wheel arches, well away from the heat and fumes of the engine bay. Compartment doors are remote-released from the cockpit, and also provide access to the equally well-insulated dry-sump oil tank and electrical equipment bays. ▪ If just one passenger is carried, more specially-designed luggage has been developed to fit into the free seat, providing a further 2 cubic feet (56 litres) of luggage space, making 10 cubic feet in total. ▪ Exclusive ‘McLaren f1’ hand-crafted luggage has been tailored specially to optimise available-space utilisation, including two tall cases, two suitcases – one hanging, one slender – and a carbon-composite document case. ▪ The custom-made carbon and leather document case fits beneath the driver’s seat, while interior cockpit stowage includes four large ‘glove boxes’ and an A4-sized map pocket. A courtesy mirror is provided for passengers’ use. ▪ A choice of interior and luggage leather colour schemes is offered, and for further personalisation the driver’s seat, steering wheel and luggage can all be colour matched to the car body or other client preference. ▪ A nose-top compartment provides space for the hydraulic reservoirs, onboard Kenwood ten-disc CD unit and the tailored titanium lightweight tool kit developed exclusively for the F1 by the well-known high quality French manufacturer Facom. ▪ The commissioning brief for this tool kit was that its constituent items should be necessarily strong, robust and usable, but also extremely light to comply with the rigorous weight target for the car as a whole. Facom has accordingly developed a kit consisting of forged titanium tools manufactured to McLaren F1 requirements. ▪ A tailored car cover and a battery charger with remote integrated connection point built-in are also supplied with each vehicle. ▪ The McLaren F1 is intended above all else to be used…

GLASS

ESTABLISHING NEW STANDARDS FOR MID-ENGINEDSPORTS CAR VISIBILITY, PRACTICALITY AND SAFETY

Glass specification for the McLaren F1 is demanding: laminated glass throughout, a large double-curvature windscreen at 23-degrees to the horizontal, featuring unparalleled fit and finish, easy recyclability, a low target weight and, above all, exceptional mass-area heating. ▪ One early F1 target was to set new standards for mid-engined sports car visibility. Hence the perennial problem of large area glass de-icing and de-misting had to be overcome. ▪ A conventional hot-air defrosting system, bulky and inefficient, was rejected in favour of electrically-heated glass throughout. ▪ McLaren Cars found just one company in Europe with the expertise and resources to create such glass technology. ▪ St Gobain of Aachen has particular expertise in automotive glass. A dedicated team was assigned to meet McLaren Cars’ demands. This imaginative approach yielded revolutionary new methods of glass assembly for improved optical quality, plus the exciting new concept of de-icing by resistive film within the glass. ▪ Plasma sprayed onto the inside of the outer glass laminate provides both its tint and heating element to offer speedy windscreen and side-window defrost and demist. It also reduces transmission of heat by 20 per cent and of ultra-violet light by 85 per cent giving protection to the interior finish and furnishing. ▪ Under EEC test conditions, the F1’s glass is completely cleared of ice seven times faster than the regulations require! Its electric demisting system further increases the F1’s already exemplary safety package by maintaining optimum vision under all weather conditions. Both cabin safety and security in the McLaren F1 are enhanced by provision of this shatter-proof laminated glass throughout. ▪ In fact, the F1 project’s glass programme provides a shining example of how Formula One thinking can encourage the automotive industry at large to improve the breed…

AUDIO SYSTEM

A NEW APPROACH TO CAR AUDIO DESIGN WAS DEMANDED, THAT THE SYSTEM BE AN INTEGRAL PART OF THE CAR

McLaren Cars asked Kenwood to create the F1’s unique audio system. Kenwood had to achieve the finest-quality sound reproduction within extremely demanding weight and design restrictions. ▪ Their system had to harmonise with the f1’s ergonomic philosophy, being easy and logical to operate under all driving conditions. As well as offering exceptionally user-friendly hi-fi controls, it also had to maintain all current state-of-the-art features and matching flexibility. ▪ Involved in the F1 project from its inception, Kenwood developed a dedicated ultra-modern compact disc system freed of current mass market compromise. The result is both unique and simple to use, and provides audio quality second to none. ▪ The system’s heart is the world’s smallest ten-disc player, a front-mounted KDC C600 compact disc autochanger using the latest Kenwood single-bit technology and offering over 12 hours continuous listening pleasure. During development testing, it has performed reliably at up to 1.5G loading – ideal for the demanding environment of the F1 in action. ▪ The F1 driver has a range of sophisticated multi-function switches within easy reach to ensure total system command without distraction from the road. Linked directly into the car’s ‘brain’, visual information appears on the dash panel warning system indicator, enabling the driver easily to confirm the functions activated. ▪ This revolutionary concept epitomises the F1’s ‘driver first’ philosophy. ▪ To power their five assorted speakers, Kenwood chose their KAC 622 amplifier. Integrated into the dashboard this new product provides easy and accurate power delivery and sound quality. Careful speaker positioning in specially designed enclosures ensures the highest quality. ▪ And thanks to the F1’s unique centreline driving position, it is the only car in the world to offer truly stereophonic sound.

FINISH

COMBINED TECHNOLOGIES RESULT IN ANALL-NEW BODY COATING SYSTEM FOR THE F1’SCARBON COMPOSITE OUTER SHELL

A genuine jewel is worth cherishing. To preserve the McLaren F1, its creators have collaborated with Sonneborn & Rieck Ltd to develop high-technology coatings and finishes for its advanced composites body. Exacting standards were set to meet the most stringent international demands in both product quality and technical performance while also ensuring that the products in question are environmentally compatible. This programme has resulted in a finish whose quality is outstanding. ▪ Sonneborn & Rieck is a British company and world leader specialising in the development and manufacture of high technology coatings and paints for the automotive industry. ▪ For the first time, S&R and McLaren Cars have worked together to combine technologies which result in an all-new body coating system for the carbon composite outer shell of the F1. ▪ This material places new demands upon the composition, adherence and elasticity of paint films. Complete adhesion is vital, yet conventional petro-chemical based treatments can potentially degrade the car’s composite surface to which they are applied, as well as being environmentally harmful. S&R is now perfecting entirely new patented coatings combined with water-based paint technology in a major step towards the elimination of petro-chemical solvent use. Some of the coatings use 100 per cent ‘solids’ formulae which have no thinning agent to evaporate and effect the environment during application. ▪ These new processes offer better durability, high abrasion and scratch resistance and minimise colour degradation. They already exceed international environmental standards due to be enforced in 1998, while still matching the high performance of conventional products. ▪ By Adopting this technology – ideal for applications to an advanced composites production car – S&R and McLaren Cars are breaking entirely new ground.

CRAFTSMANSHIP

INNOVATIVE DESIGN AND ENGINEERING SKILLSDRIVEN BY THE BEAUTY AND EFFICIENCY OFFORMULA ONE COMPONENTRY

Everyone involved in creating the McLaren F1, from the technical staff who conceived it, through the design engineers who drew it, to the pattern makers, fabricators, machinists, composites specialists…every crafts and tradesman who physically make it – is an artist in his own right. ▪ A truly classic car – and throughout history there are few indeed – is rare, exclusive, innovative, trend-setting, exciting, thrilling to drive and scintillating in performance. ▪ Individually, in their componentry, they are also exquisitely well made. ▪ How many enthusiastic collectors throughout the motoring world cherish like precious icons perhaps a supercharger volute from the 1920s, a hollow axle from the 1930s, a multi-cylinder engine from the 1960s? Each artefact embodies care, craft, superb design, superlative skill. The kind of automotive objet d’art one might love to place upon the desk, occasionally to be caressed, handled, displayed and demonstrated… ▪ The McLaren F1 project has been one of enthusiastic heart and soul – frontier design and engineering driven by the beauty and efficiency of Formula One componentry. ▪ F1 materials and finishes have all been chosen for absolute performance, but the most elegant of functional concepts has a flair and beauty entirely of its own. ▪ Every part of the McLaren F1 – whether it be cast in magnesium, machined from solid aluminium or fabricated in titanium or Inconel – perhaps moulded and cured in the most advanced carbon composite – or indeed, like the gearlever knob and handbrake handle, traditionally turned and carved from African blackwood – exemplifies skill and care and exquisite craft. ▪ Where an Old Master painting may be the work of one great artist labouring alone, a truly classic car combines the work of many… ▪ And the McLaren F1 now joins that rarefied, exclusive, brief list of Truly Classic Cars… ▪ An abiding work of many artists’ hands – a thing of beauty – a highly usable joy forever.

You must be logged in to post a comment.