The flat-six engine

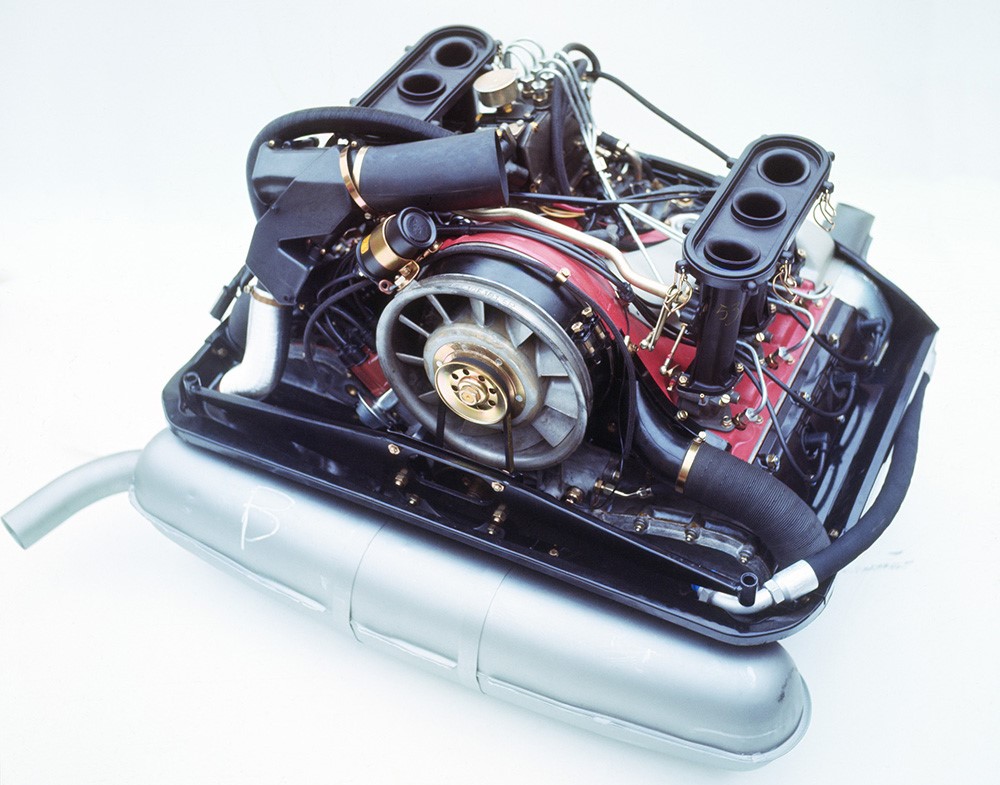

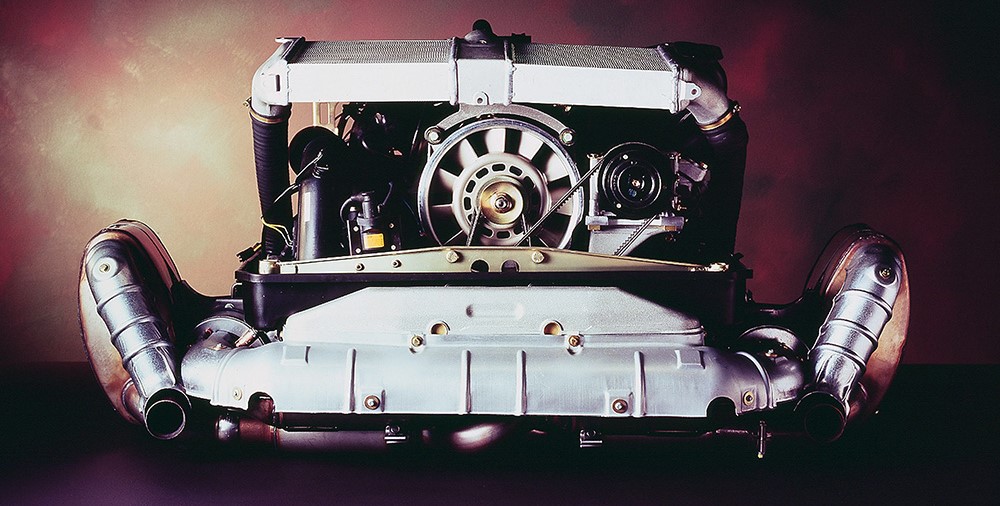

In coming up with the conceptual design for a new engine in the 356 successor, it was clear from the outset that it would be a rear engine. Under the leadership of the nephew of Ferry Porsche, Ferdinand Piëch, an air-cooled six-cylinder flat engine was created with an axial blower and – due to its higher rev reserves and more refined running properties – one overhead camshaft per side. The camshafts were chain driven after bevel shafts or toothed belts were retired. The initial specification called for 2 litres of displacement with a potential for increases up to 2.7 litres. At that time, none of the Porsche technical specialists could have foreseen that this engine type, in its basic form, would be continued up to the year 1998 or that its displacement would reach 3.8 litres.

The flat engine was air-cooled up to and including the type 993. Then engineers switched over to water cooling – one benefit was that this let them move into new performance classes. At first, this shift met with scepticism by many enthusiasts, and for some purists it still represents a break with 911 history. But in the view of automotive experts, the shift to water cooling did not by any means water down the total 911 package, rather just the opposite was the case. Its importance has increased in every model series ever since it was introduced.

The six-cylinder flat engine of the type 901/911 generated a power of 96 kW (130 hp) at 6,100/min from 2 litres displacement. For the sake of completeness, a brief mention should also be made of the Porsche 912 here. It was launched in parallel with the 911 in spring 1965; it was a lower power version and had the four-cylinder engine of the type 356 with a displacement of 1.6 litres and 66 kW (90 hp) of power. It was fitted with simpler features than in the 911. The 912 was produced in the Coupé and Targa body forms until summer 1969.

Starting in model year 1967, the power-boosted 911 S version produced 118 kW (160 hp) at 6,600/min – and the “normal” 911 soon carried the model identifier 911 L, and later 911 E. Engineers were especially proud of having achieved this power boost in the 911 S and a power-to-displacement ratio of 80 hp per litre without any reduction in engine life. Starting in 1967, there was also the 911 T with reduced power output (81 kW/110 hp at 5800/min), which was designed as an entry-level model.

The first vehicles to feature engines with an emissions control system were offered in the USA in 1968. Porsche succeeded in fulfilling emission regulations in the USA – including especially strict rules in California – without compromising car performance and with nearly identical ride comfort. Emissions were controlled by exhaust gas recirculation in the induction manifold and by thermal reactors. Porsche was the first company in Europe to install emission test benches for its development work.

In autumn 1968, Porsche introduced mechanical petrol injection. There were new engines for the 911 E and the 911 S – the first produced 103 kW (140 hp) at 6500/min, while the second produced 125 kW (170 hp). Both engines were designed with an eye towards further power increases. From the outset, their emissions behaviour was developed to meet the strictest regulations. The six-cylinder flat engines had sodium-filled exhaust valves –this technology from motorsports guaranteed that the engines could handle sustained full throttle operation.

More engine displacement resulted in more power and torque; it was first increased to 2.2 litres in 1969, then to 2.4 litres two years later. In the 911 S, for example, this initially boosted power to 132 kW (180 hp) and then to 140 kW (190 hp). In 1971, to satisfy in -creasingly more stringent emissions regulations, the engine’s compression ratio was also reduced so that all 911 cars could continue to be driven with regular petrol worldwide. In 1972, the K-Jetronic made its debut, initially for the USA. A new six-cylinder model debuted in the same year: the Carrera RS with a 2.7-litre engine, 154 kW (210 hp) at 6300/min and a torque of 255 Newton metres; it had a very low unladen weight of 1075 kg with standard equipment. In 1973, all engines were switched over to 2.7 litres displacement in the G model; at the same time, the use of regular unleaded petrol was enabled – Porsche was proving that sports cars could be eco-friendly as well. In 1974, 111 units of the Carrera RS were built with 3-litre engines as homologation vehicles for Group 3.

1974: Beginning of the 911 Turbo era

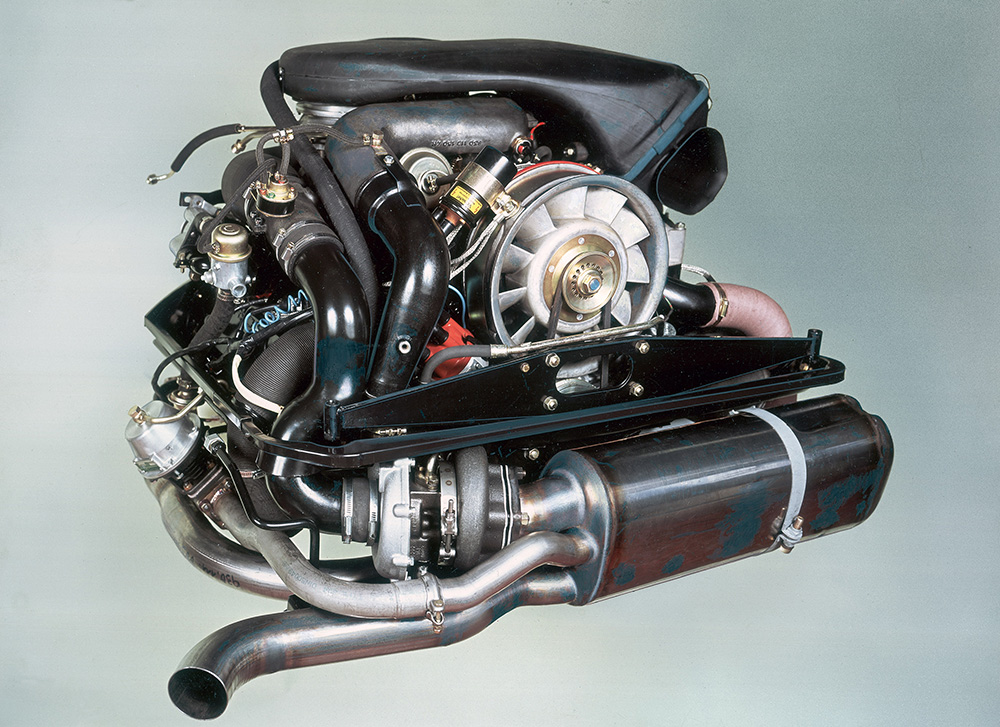

Another legend made its debut in 1974 as well: Porsche introduced the 911 Turbo, the first production sports car with a turbocharger. The manufacturer had transferred its extensive experience with charged engines from motorsports to series production. The engine was based on the engine of the 911 Carrera RS 3.0, it produced 191 kW (260 hp) and a torque of 343 Newton metres and accelerated the car to a top speed of over 250 km/h.

In the year 1976, continually more stringent emissions regulations had to be satisfied, especially in the USA, Canada and Japan. Initially, vehicles for these markets received complex emissions control systems. Meanwhile, the types 924 and 928 appeared, and in 1977 the company reduced its 911 line-up to the 911 SC (3 litres displacement, 132 kW/180 hp) and 911 Turbo models. The Turbo got an engine with a higher 3.3 litres displacement that was also equipped with an intercooler. The results: a solid 221 kW (300 hp) at 5500/min and a torque of 412 Newton metres.

Porsche built the first engines with regulated catalytic converters in 1980. Over the course of their design revisions, they received an oxygen sensor whose signals were processed in a controller and were used directly for mixture control. In 1979, the power of the 911 SC was also boosted to 138 kW (188 hp), then one year later to 150 kW (204 hp) at 5900/min.

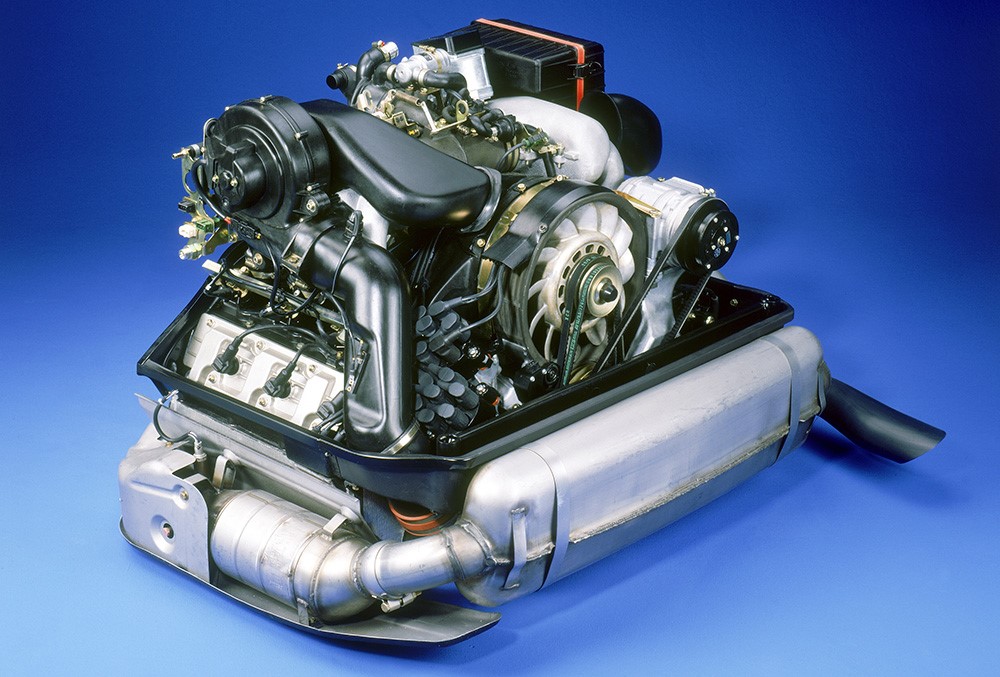

A new generation of naturally-aspirated engines was presented in 1983 with 3.2 litres of displacement and digital engine electronics. All engines were now prepared for unleaded regular petrol – this fuel was still unavailable in many European countries, so this modification would permit a flexible reaction to its availability. In the 911 Carrera, the engine produced 170 kW (231 hp) at 5900/min and delivered a torque of 284 Newton metres (for USA and Japan: 152 kW/207 hp and 260 Newton metres). There was one disappointment, however: Customers in the USA had to do without the 911 Turbo for several years, because its engine was not configured for the use of a catalytic converter. It would return in 1985 with 210 kW (282 hp) of power.

The Carrera 4 made its debut in 1988 and received a new engine with 3.6 litres displacement; it produced 184 kW (250 hp) at 4800/min and offered a torque of 310 Newton metres. One unique aspect was that it featured two spark plugs per combustion chamber to assure better combustion. The Carrera 2 introduced one year later – which replaced the previous 911 with rear-wheel drive and a naturally-aspirated engine – also got this engine.

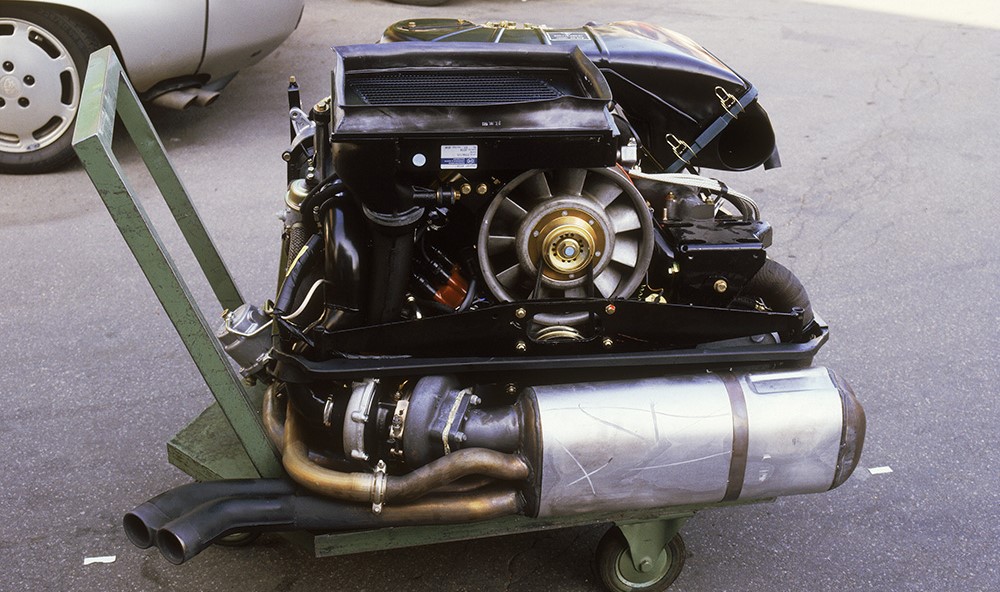

The year 1990 saw a new edition of the 911 Turbo with a new engine. Its features included thermally optimised cylinders and cylinder head seals made of stainless steel. The engine now developed 235 kW (320 hp) at 5750/min and a torque of 450 Newton metres from the same 3.3 litres of displacement. One year later, a fine delicacy for motorsport oriented customers made its appearance: the 911 Carrera RS, whose 3.6-litre engine was powerboosted to 191 kW (260 hp). Its actual highlight was a low gross weight of 1120 kg (with manual gearbox) compared to the 1350 kg of a Carrera 2. Since the RS could not be registered in the USA, the RS America was sold in this market which featured engine technology of the Carrera 2 plus sport chassis and a rear spoiler. In 1992, the Turbo S was introduced – of which only 86 units were produced; its engine developed 280 kW (381 hp) at 6000/min and a torque of 490 Newton metres. Its successor followed in 1992: the 911 Turbo 3.6 with 265 kW (360 hp) whose higher power – compared to that of an equivalent naturally-aspirated engine – was primarily obtained from higher charge pressure and a modified ignition map. Its torque was 520 Newton metres.

In 1993, various modifications were made to the Carrera engine in the just introduced 993 model series to boost its power to 200 kW (272 hp) while retaining the same engine displacement and compression ratio. These modifications included a torsionally stiffer crankshaft, improved and lighter connecting rods, lighter and further improved pistons and a die-cast aluminium engine block with nickel-silicon coated running surfaces. For motorsport, a short production run of the 911 GT2 was made; with two turbochargers its 3.6-litre engine could develop 316 kW (450 hp) at 5750/min (street version: 316 kW/430 hp). The Turbo also adopted the biturbo concept, and another global innovation was the OBD II emissions system monitoring. Now producing 300 kW (408 hp) of power, the engine was indeed based on the 3.6-litre naturally-aspirated engine, but it was so extensively modified that it was essentially a new design. Its features included a different camshaft, reinforced connecting rods, pressed and coated pistons, pressed alloy cylinders with surface coating and lengthened intake ports.

1977: Charge air cooling

One of the secrets of the success of the 911 series is that it has been enhanced constantly and systematically. Each year, lots of small details on the 911 have been improved so that it has become closer and closer to Ferry Porsche’s ideal image of a perfect sports car. This philosophy was also applied to the 911 Turbo. The main features of the 911 Turbo, reworked in 1977, were an increased displacement of 3.3 litres and a charge air cooler positioned underneath the rear spoiler. Derived from the field of motor racing, it was a world first in a series production car. The charge air cooler reduces the intake air temperature by up to 100 degrees Celsius, thus enabling the engine to achieve higher output and torque in all engine speed ranges – cooler gases are denser and therefore charge the engine more effectively. The result was a stable 300 hp at 5,500 rpm and a maximum torque of 412 Newton metres. Furthermore, the charge air cooling also reduces the thermal load on the engine. The exhaust gas temperatures fall, as do the emissions, and fuel consumption is reduced. Another advantage is the improvement in antiknock properties – excess temperatures causing the mixture to self-ignite is virtually ruled out.

1995: Bi-turbocharging

The 993 series 911 Turbo, presented in 1995, was given a 3.6-litre engine fitted with two small turbochargers, whose performance curve was not dissimilar to a high-displacement naturally aspirated engine. From as low as 2,000 rpm, the engine generated plenty of thrust which changed into impressive, rousing velocity from 3,500 rpm and pressed the occupants into their seats. In addition to the output that increased to 300 kW (408 hp) and the rise in the maximum torque to 540 Newton metres, the Weissach engineers also aimed to reduce the engine’s acceleration turbo lag to a previously unknown minimum. They achieved this by using two small turbochargers instead of one large one, whereby the low moment of inertia of the smaller blades had the most significant effect. The two regulated turbines with integrated bypass flap generated a boost pressure of 0.8 bar. The impressive increase in output and engine speed was also due to optimisation of the charge cycle, the high level of efficiency of the two charge air coolers and the knock control system that facilitated running the engine at optimum efficiency

1995: OBD II emissions control system

Another technical highlight of the six-cylinder car was the new OBD (onboard diagnostics) II emissions monitoring system which was used for the first time by a series production manufacturer. It facilitated early detection of faults or defects in the exhaust and fuel system. The extensive measures for reducing emissions were very effective on the 911 Turbo. To the great surprise of the experts, the turbo engine turned out to be the lowest emission series production engine in the world. The supercharged 993 was also the first bi-turbo with air mass control in automotive history. The OBD continually monitored the operation of the entire exhaust system with catalytic converters and oxygen sensors, the functioning of the tank ventilation system with activated charcoal filters, the secondary air system and the fuel system. Misfiring was also recorded. At the time it was launched, OBD II was already mandatory in the USA and other markets soon followed. OBD required a great deal of development work and an extremely complex engine management system.

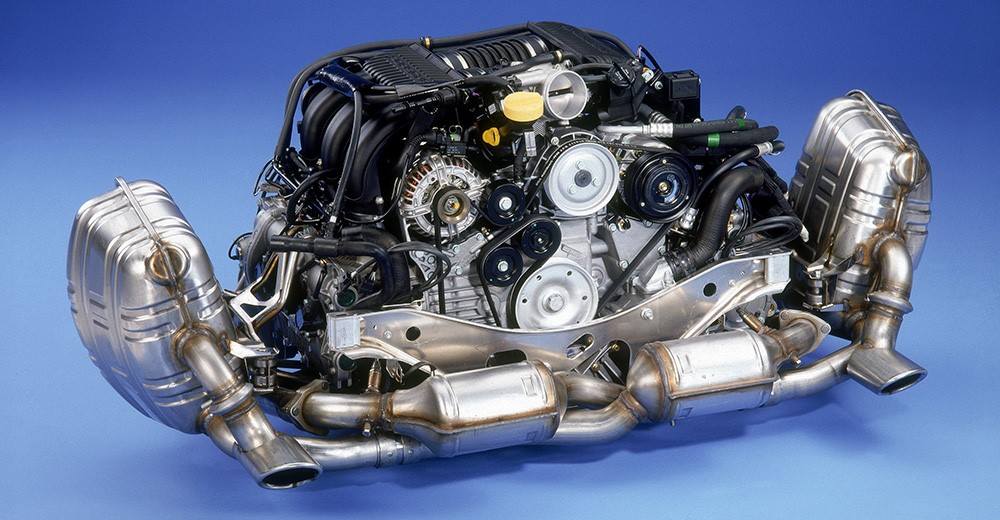

1997: The first water-cooled Porsche six-cylinder engine

In 1997, the 996 model series made a quantum leap in 911 history. It not only got a completely new body, but also a water-cooled flat engine. The engine, with its 3.4 litres displacement, was significantly shorter (by 70 mm) and much lower (by 120 mm) than the previous engine. It produced 221 kW (300 hp) at 6800/min and was much better at high revving than the previous naturally-aspirated engine. However, its key design properties were unaltered: six-cylinder, seven-bearing crankshaft, dry sump lubrication, dual-mass flywheel and a longitudinally split engine housing. Only available in the 911 Carrera at first, one year later the new engine was also offered in the Carrera 4, and the Turbo was also switched over to water cooling. Then there was the GT3, whose naturally-aspirated engine was based on that of the GT1 but developed 265 kW (360 hp) at 7200/min. In 2000, the Turbo re -ceived a new engine (309 kW/420 hp at 6000/min, 560 Newton metres) that was derived directly from the GT1. It simultaneously served as the basis for the new GT2 (340 kW/442 hp at 5700/min, 620 Newton metres).

Displacement was increased for the naturally-aspirated engines in 2001, it was now 3.6 litres in size. That was sufficient for a power boost to 235 kW (320 hp) at 6800/min and a torque of 370 Newton metres. The improved biturbo engine in the GT2 now produced 355 kW (483 hp). The GT3 RS, which launched in 2003 and was primarily intended for motorsports, had a higher power output of 280 kW (381 hp) that was primarily due to its higher revving capabilities and an adjustable camshaft.

The next generation 911 of the 997 model series appeared in 2004. The 3.6-litre naturally-aspirated engine of the Carrera was preserved, while the Carrera S was distinguished by a new engine. From 3.8 litres displacement, it produced 261 kW (355 hp) at 6600/min and developed a torque of 400 Newton metres. The next GT3 (305 kW/415 hp) was also based on the 997 model series; it was presented at the Geneva International Motor Show in March 2006. One year later, the next GT2 appeared, whose biturbo engine produced 390 kW (530 hp) at 6500/min. In 2008, the 911 and 911 S models then received fundamentally new engines with direct petrol injection. At the same engine displacements, they produced 254 kW (345 hp) at 6800/min and 283 kW (385 hp) at 6500/min, respectively. Using direct petrol injection, combustion can be controlled more precisely according to specific operating states, which has resulted in significant fuel savings.

“Downsizing” for improved fuel efficiency became a guiding design principle for engine engineers starting around 2008. Exploiting its bundled knowledge, Porsche developed new downsizing technology for the 911 of the 991 model series, which appeared in 2011: For example, the flat engine in the 911 Carrera (257 kW/350 hp at 7400/min, 390 Newton metres) was given a displacement of 3.4 litres instead of the previous 3.6 litres. The Carrera S (294 kW/400 hp at 7400/min, 440 Newton metres) retained its 3.8 litres of displacement.

Both of these vehicles illustrate how the 991 model series has been reengineered for maximum fuel efficiency in a total package. With a weight-to-power ratio of 3.5 kg per hp, the new 911 Carrera S is at the top of its competitive field. And in terms of NEDC fuel consumption, the 911 Carrera with 8.2 litres per 100 km and the 911 Carrera S (with 8.7 litres) each with Porsche Doppelkupplung – once again exhibit top values. At the same time, they are the latest statements by Porsche that it is always the engine that is the heart of a sports car – that power and efficiency are not mutually exclusive and have never been in the 50 years of 911 history at Porsche.

1983: Digital engine electronics

Digital engine electronics (DEE) celebrated its debut in 1983 with the new naturally aspirated engine with 3.2-litre displacement. Its most important advantages were better fuel consumption, cleaner combustion and therefore maximum power output. The system worked with a shared control unit which all the engine’s operating states were programmed into. The correct injection quantity and the exact ignition point were assigned to each engine speed, each accelerator position and temperature. The overrun fuel cutoff, i.e. no fuel was consumed when the engine was overrunning, and electronic idle speed control when auxiliary components were activated were useful additions provided by the digital engine electronics. The knock control system ensured “healthy” engine operating conditions. DEE is combined with various injection systems, depending on the engine.

You must be logged in to post a comment.