Honda Research and Development engineers have long held the dream of producing a world class sports car. With the decisionto create the Acura Division, an appropriate channel became availablefor the distribution of an automobile of this caliber. This automobile would become both a rolling showcase for the firm’s technical prowess, and also establish the “performance/luxury” image the Acura Division needed to achieve if it were going to be recognized as a leader in that market segment.

The car that was to become the Acura NSX was envisioned as being not merely a competitor for the exotics and near-exotics already on the market, but a groundbreaking vehicle that would provide the emotional and visceral excitement which is part and parcel of driving an exotic car, and embody the unique Honda spirit.

To understand the how and why Honda even considered building a car like the NSX, it’s first necessary to understand the spirit and the high level of car enthusiasm that suffuses every aspect of Honda’s worldwide organization. Historically, Honda has always been a “racing” company. From its initial interest in motorcycle racing in the ’60s , to its current dominance in FormulaOne, Honda has always taken racing as a serious endeavor. And its involvement with motorsports was never an afterthought or promoted on an occasional basis as an adjunct to the latest marketing strategy. It was an integral part of Soichiro Honda’s philosophy, a philosophy that was nurtured and encouraged and placed at the core of Honda’s approach to building cars. As a result, the enthusiast ethic, the idea that cars, no matter what their market niche, should be amply endowed with a large dose of driving fun, is part of everyone’s job description. It comes with the territory.

The Honda spirit and mindset, while multi-faceted, can be encapsulated as “an intense emotional involvement with cars.” As Honda sees it, driving isn’t merely a method of achieving a destination. It should alsobe a recreational activity that frees the mind, excites the senses and provides a means for relaxation. Part of that excitement is the result of a human-oriented approach to car building, an approach which recognizes that all a car’s priorities should be devoted toward entertaining and satisfying the driver. Whether it involves the shape of a shifter knob or the shape of the torque curve, it has to make sense to the driver and make his time behind the wheel both intriguing and pleasing. That approach further recognizes that it takes much more than raw horsepower or high lateral acceleration numbers to satisfy a dedicated, knowledgeable sports car owner. What that type of driver demands above all is balanced performance.

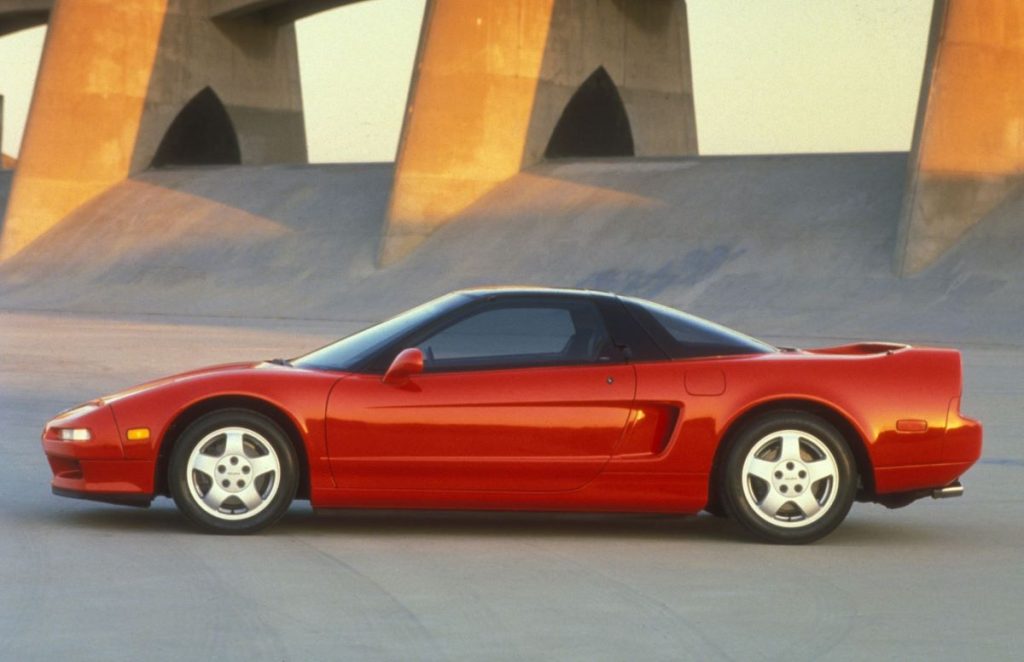

Stated simply, the intention in creating the Acura NSX was to produce a handbuilt, exotic, mid-engine sports car that would establish entirely new levels of performance, refinement, driveability and reliability.In essence, the NSX is intended to represent an entirely new definition of the exotic sports car.

Concept and Goal

The NSX project was initiated in 1984. The engineers at Tochigi Research and Development Center created a list of attributes the future NSX had to possess. First on their list was top-rank performance on a level equal to or greater than the existing exotics. Their interpretation of performance was not narrowly defined to a few areas such as power, handling and brakillg, but included areas that are often given less attention by the traditional builders of exotica.

Crucial to this concept was liveability.The car had to be as easy to live with as any other Acura product despite the very high performance goals. That meant incorporating such attributes as excellent visibility, comfort, reliability in all components, and active and passive safety systems.The challenge they saw was integrating these concepts, which are in many cases mutually exclusive, into a midengine high performance car.

In their survey of the extant exotic and sports cars, the project leaders saw a clearly delineated map. One section contained the limited-production exotics such as Ferrari, Lamborghini, Lotus, and the more rarified versions of the venerable Porsche 911. Aside from the mid- or rear-engine configuration, this class of car is characterized by a heavy emphasis on engine power and the first priority is given to packaging the mechanical components. They are also the sort of cars that demand constant attention, both in service and maintenance and when driven quickly. Part of the cachet of these vehicles is the fact that they’re sometimes idiosyncratic, quirky and have to be mastered or coerced into submission by a very skilled driver. Their ergonomics are often far from ideal- something which can be perceived as either anachronistically charming, or just exasperating. This type of car, while great fun to drive on an occasional basis, may become tiresome when driven daily or on a long trip. Although their power to weight ratios and visceral thrills are desirable qualities, the Acura NSX would not be a car just for Sunday afternoons.

On the other end of the sports car spectrum are the lightweight, mass-produced sporty cars like Miata and MR2. While these vehicles provide a high degree of reliability and fun at an affordable price, they don’t possess the very high levels of performance the project leaders envisioned for the NSX. Their most desirable traits are light overall weight and good ergonomic packaging. They can be driven easily at moderate speed and make no unnecessary demands on the driver.

Occupying the middle ground are the middle weight mass-production cars like Corvette and 300ZX. These are certainly livable sports cars with sufficient performance to satisfy an enthusiast. Their priorities include comfort and convenience. And while they can excel in certain areas, their overall performance is compromised due to their high overall weight and abundance of luxury features. The Acura NSX was envisioned as stretching the current sports car envelope. It would occupy a segment that was philosophically much closer to the lightweight, highly responsive characteristics, of a Formula One car than either the traditional heavyweight sports cars or the middleweight sports/touring machines. It was to be a synthesis combining the light weight of a “sporty” car, the power output, looks, performance, limited production, and packaging of an exotic, and the ergonomics and livability of a middleweight sports car. Most importantly, the Acura NSX was to be a car that could be driven very, very quickly, and right to the limit without extraordinary efforts by the driver. There would be no need for the driver to accommodate himself to quirky handling characteristics, disturbing drop-throttle oversteer or any of the other negative attributes commonly associated with exotic sports cars. Oearly, this was an ambitious goal. Nothing like the NSX has been attempted before and, if successful, the NSX would redefine the meaning of an exotic.

In order to fully express the Honda spirit, the project team knew the NSX must not be a clone of an existing exotic, nor an upgraded, limited-production version of a mass-produced car. They also knew it had to have extremely high limits, fast but linear responses, light weight, packed with the latest technological advances and provide excellent reliability. But the question they asked themselves was how do you hit a target when no one has yet etched the boundaries of that target? The NSX was staking a claim on unknown territory and the real problem was figuring out how you get there from here.

To give the goal a fixed point of focus, the project team turned for inspiration to the General Dynamics F-16 Falcon. This all-weather air-superiority aircraft embodied virtually everything they envisioned for the NSX. It’s the latest iteration of the single seat dogfighter, a light weight, very responsive, highly maneuverable single engine interceptor with an awesome performance envelope and dizzying thrust to weight ratio. Clearly, the NSX wouldn’t attempt to equate itself with this fighter, but the basic principles of light weight, responsiveness and maneuverability could successfully be emulated and carried over from aircraft to sports car. With the image of the F-16 fixed in their minds, the project team began the task of setting definite weight and power targets and sketching the basic parameters of the NSX.

In order to achieve the intended performance target, they postulated that the NSX would require a power-to-weight ratio of 5.0 to 5.5 kg./hp (11.0 to 12.1lbs./hp). And to achieve the handling and response targets, the car should weigh under 30001bs. With that weight, the engine would need to produce at least 250 hp to maintain the power to weight ratio. By using engine control technology that was already in progress, it was clear that a normally aspirated V6 was the optimum engine configuration to achieve the required horsepower target, quick throttle response and free-revving capabilities. A V6 was the right size, it offered the low weight and produced enough power to achieve the intended goals.

The question of weight however wasn’t as easily addressed. A mid-engine car is inherently heavier than a front-engine car due to the large amount of structural reinforcement necessary to produce a rigid monocoque chassis. Building a steel chassis with a wheelbase long enough and a track wide enough to allow an amply sized, comfortable cockpit, adequate trunk room and a large enough engine bay, would have exceeded the 3000 lb. weight target. The engineers were unwilling to make this compromise because it would have a negative impact on the agile, responsive handling they desired. The only logical solution was to explore weight reduction techniques. Building on existing research and on a newly launched research endeavor, the team concluded that aluminum was the only material that could accomplish this goal.

Finally ,to provide the exclusivity a car of this caliber deserves, it was decided that the NSX should be built in low volumes in a new production facility dedicated exclusively to its manufacture.

Overview

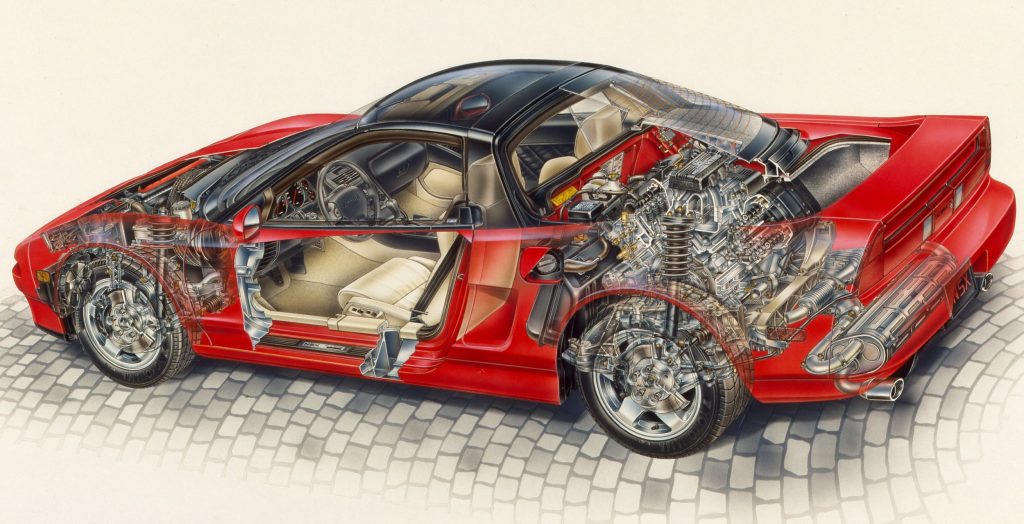

The mid-engine, two-seat Acura NSX is powered by an all-aluminuml 3.0-liter V6 which produces 270hp and 210lbs.-ft. of torque. The normally aspirated engine is equipped with dual overhead cams, four valves per cylinder,Variable Valve Timing and Lift Electronic Control (VTEC), and a Variable Volume Induction System.The engine also offers Programmed Fuel Injection and a Direct Ignition System which uses an individual coil mounted atop each spark plug instead of a single coil. To help ensure high engine speed durability,specially developed titanium connecting rods are used. A five speed manual transaxle is standard with an electronically controlled 4-speed automatic available as optional equipment. Standard equipment with the automatic is a variable-assist, speed sensitive electric power rack-and-pinion steering system.

The NSX features all-aluminumunit body construction for light weight. The all independent suspension also features aluminum alloy control arms and hub carriers front and rear, and an aluminum cradle for the front and rear suspension. The braking system features four-wheel ventilated discs front and rear and an advanced 4-channel Anti-Lock Braking System. A sophisticated Traction Control System has been designed to limit wheelspin and help enhance control on slippery surfaces. The vehicle dimensions are as follows:

| Wheelbases | 99.6in (2530mm) |

| Track F/R | 59.4in (1510mm)/ 60.2in (1530mm) |

| Overall Length | 173.4in (4405mm) |

| Overall Width | 71.3in (1810mm) |

| Overall Height | 46.1in (1170mm) |

| Curb Weight | 3010lbs(1365kg)- 5-speed 3098lbs (1405 kg) – Automatic |

An assembly plant, dedicated exclusively to the manufacture of the NSX has been built on the grounds of Honda’s Research and Development Center in Tochigi. The plant utilizes unique assembly techniques based on highly experienced assembly teams and eliminates the traditional assembly line to build a distinct, hand-crafted sports car. Production of the NSX is a maximum 25 vehicles per day. A total of 3000 cars are scheduled for delivery to the U.S. in the first full year of production.

1991 Acura NSX – Suspension

Suspension

The desired goals for the NSX suspension went well beyond the typical goals of high lateral adhesion, transient response and linear response to control input. The engineers wanted a suspension that allowed the driver to easily control the car right to the limit. Virtually all the exotics the engineers evaluated exhibited shortcomings in the two crucial areas of “feel” and “ease of control.” They became tiresome to drive at speed for extended periods of time. They wanted the NSX to be always rewarding and never tiresome.

A major design target was reducing unsprung weight to the lowest possible values. Low unsprung weight makes it easier to control wheel motions to maintain tire contact, manage vertical loads and provide precise response to steering input. To this end every suspension component is made from an aluminum forging or casting. The suspension components in total are more than 20 kg. (44Ibs.) lighter than comparable steel components.

The basic configuration is similar to that of a Formula One car in that it employs an upper and lower control arm (or double wishbone) design with a coil-over shock absorber and anti-roll bar front and rear. The rear suspension also has an additional lateral link for greater wheel control. All the suspension arms are made of extremely rigid and durable forged aluminum. The front steering knuckles and the rear hub carriers are made from aluminum castings. The springs are straight rate with an extended rubber bump stop which acts as a progressive springing element at the limit of wheel travel.

The shock absorbers are gas filled and feature a newly designed HPV piston and bottom valve which opens progressively under vertical loads. The progressive opening of this valve produces a more favorable damping profile and more precise damping control than a conventional valve system in which the fluid control orifices are either fully opened or closed.

The front and rear suspension components are mounted on a separate subframe. These subframes consist of aluminum forgings, castings, extrusions and stampings for light weight and highrigidity.

The main difference between the NSX and a Formula One suspension, of course, is that while a Formula One car makes no allowances for ride quality, good bump absorption or generous wheel travel, the suspension on the NSX had to be designed to have those properties as well.

To that end, the suspension development program was far-ranging and took place at the Tochigi Proving Grounds, the Suzuka circuit and the long Nurburgring course in Germany. In addition to the standard evaluations conducted in-house by the suspension engineers, the car was subjected to evaluation by top rank drivers such as 1988 Formula One World Champion Ayrton Senna, Indianapolis 500 winner Bobby Rahal, and Japan’s Satoru Nakajima.

It’s a known fact that in developing a racing car, or any high performance system, the big gains can be made fairly easily and quickly. A month of solid work, for example, can achieve 80 or 90% of the desired suspension tuning. But it can take several more months to achieve the next 5% and many more months beyond that to achieve those final few percentages which very often spell the difference between a suspension which is merely good and one that’s a hands-down winner. The contributions of these drivers were invaluable in extracting those crucial percentage points. The one thing the suspension development team didn’t have to worry about was chassis rigidity.A chassis with insufficient torsional rigidity will cause unwanted movement in suspension components. This will in turn undermine even the most carefully calibrated suspension system.The NSX aluminum unit-body structure was sufficiently rigid, however, that development engineers could concentrate their efforts completely on calibrating the suspension and not in compensating for a flexible platform.

Front Suspension

The front suspension uses an upper and lower control arm (also known as double wishbone or double A-arm), a compliance pivot which is used as the mounting point for the forward pivots of both upper and lower control arms, an anti-roll bar and a coil over, nitrogen gas-filled shock absorber. The geometry at the front uses a large caster angle and small trail geometry to enhance straight line stability and a light steering feel.

Although light and compact, the forged aluminum control arms, both front and rear, the compliance pivot and the rest of the aluminum suspension components are extremely strong units. The design was optimized using the latest computerized stress analysis programs and the strength, durability, impact resistance and corrosion resistance targets were verified by extensive laboratory and track testing. They are equal in strength to steel units but are roughly half the weight.

As is already well-known, the number one enemy of any suspension development program is unwanted toe change under dynamic conditions. Toe change occurs when the wheels are deflected from their desired steering direction by vertical or cornering loads or braking. In a cornering situation, severe lateral loads are imparted to the wheels, the control arms and control arm bushings. In some suspension systems these loads will deflect the bushings and the control arms thereby allowing the front wheels to deflect as well. Although this deflection at the wheels is small, nonetheless it translates into sloppy, imprecise handling. It causes the driver to constantly adjust steering input to compensate for this deflection and makes the car hard to drive. This compliance steering is caused by uncontrolled compliance of suspension components to lateral loads.

Similarly, toe change occurs when the wheel encounters a bump and deflects the wheels from the intended track. This bump steer is caused by the vertical movement of the suspension arms rather than bushing compliance.

Standard solutions to these problems (extremely stiff bushing material, very high spring rates and hard damping) are effective to a great degree in controlling toe change, but they produce a host of negative side effects such as poor bump absorption, stiffer than acceptable steering, ride harshness and poor steering feel. While this approach has been used in many exotics, it’s a solution more appropriate to a race car but not considered acceptable for a new generation exotic like the NSX.

The solution adopted for the NSX was not to over-control wheel motion with excessive spring force and hard bushings, but rather to design in a beneficial amount of toe-change and deflection which would enhance handling and precision.

A key element to accomplishing this was the development of a compliance pivot. Like the other suspension components, this strut is an aluminum forging. It is used as the mounting point for the front pivots of both upper and lower control arms. Under vertical bump loads the compliance strut bushings are allowed to deflect a predetermined amount and allow the pivot to rotate minutely about its vertical axis. Because both control arms are attached to the pivot, the net effect of the pivot rotation is to allow both control arms to move rearward in unison maintaining static toe geometry throughout the control arms’ vertical travel. Without the pivot, this static geometry and toe control would be difficult to maintain because the rate of deflection of the upper and lower control arm bushings would not necessarily be the same throughout the full wheel travel. With the compliance pivot, toe change is maintained at 0.2 Deg. toe-in at full compression and 0.2 Deg. toe-out at full rebound, a condition which ensures that the front wheels of the NSX will be unaffected by lateral or vertical loads and will track precisely to steering wheel input.

Rear Suspension

The rear also uses an upper and lower control arm design, coil over shock absorber, a lateral control arm and an anti-roll bar. The hub carrier is made of cast aluminum. The rear suspension is mounted on a cast aluminum sub-frame which is mounted to the chassis.

Like the front, the rear suspension is also subject to a certain amount of compliance and bump steer. They are subjected to torque loads imposed by the driveshafts which do create bushing and control arm deflection under acceleration, deceleration, cornering and braking.

To overcome this, the upper and lower control arm bushings and the geometry were optimized to produce desirable deflection under given conditions. Under braking, acceleration, and during suspension compression, toe change at the rear is allowed a small degree of toe-in. Under braking and acceleration, this toe-in enhances straight line stability. During cornering, controlled toe-in under compression yields quicker and more responsive turn-in and helps to steer the car through a comer.

Additionally,the suspensionwas optimizedto enhance anti-dive under braking and anti-squat under acceleration.

The net result of the development program is a sports car which remains virtually neutral up to the limits, is without quirky handling behavior such as drop throttle oversteer, and not only offers extremely high levels of lateral adhesion and responsiveness, but also makes the NSX easier to drive at the limit.

Brakes

It goes without saying, that a sports car needs brakes that can match or exceed the car’s overall performance potential.

The NSX is equipped with 4-wheel ventilated disc brakes and dual piston steel calipers. The diameter of the front and rear discs are 282 mm (11.1 in.). Total brake swept area is 2960sq cmand the swept area to weight ratio is 1966.8sq cmlton.

Aluminum calipers were considered, but their larger size, compared to steel, would have created the need for larger wheels which, in turn would have increased the amount of kingpin offset. Greater offset would have a negative impact on steering feel, kickback and ride quality.It was also found that aluminum calipers produced unfavorable side effects such as caliper flex and poor fade resistance.

The braking targets were to set new standards of braking performance, fade resistance, provide good pedal feel, linear braking response and low pedal effort. The development program was conducted both in the laboratory and on the Honda R&D Tochigitest track and the Suzuka and Tsubuka race circuitsin Japan.

Also, during the lab and track testing, a newpad material was developed in conjunction with Akebono. At racing speeds, brake performance of this material surpassed the leading competitors by a significant margin.

Four-Channel Anti-Lock Braking System

Developed by Honda R&D this newly developed 4-channel anti-lockbraking system controls each wheel independently with a new 16-bit micro-processor. This four-wheel, independent capability allows much finer control of the anti-lock function especially when the car is braking on a surface with a split coefficient of friction – for instance if the left side wheels are on snow, ice or standing water and the right side wheels are on dry pavement. Applying maximum braking pressure in this situation, 4-channel antilock braking allows the driver to retain maximum directional stability and steering control for the given conditions.

The basic configuration is independent parallel hydraulic circuits. In addition to the primary, non-anti-lockbraking circuit, the anti-lock system has its own hydraulic reservoir, pump, modulator unit, solenoids and control pistons. If a failure in the antilock braking hydraulic circuit should occur, normal braking force will be fully retained by the primary braking circuit. This 4-channel system fully exploits the enhanced braking abilityof the NSX’s midship layout because the weight of the car is distributed nearly equally to each wheel. The NSX is the only car available in the U.S. with a 4-channel anti-lock braking system.

Variable Ratio Rack-and-Pinion Steering System

NSX models with the manual transmission are equipped with a variable ratio manual, rack-and-pinion steering system. To ensure maximum reliability, it features a sealed gearbox design. Precise geartooth engagement ensure linear progressive response to steering input. Steering wheel turns lock-to-Iock are 3.2 and steering gear ratios vary from 18.2 to 20.8:1.

Variable Electric Power-Assisting Steering System

Available only on the automatic transmission-equipped NSX, this power-assist steering system is the first of its kind on the American market. The system consists of a rack and-pinion steering gear with an electric motor installed concentrically around the steering rack. The motor transmits its power through a recirculating ball mechanism to the rack.

The rack-and-pinion steering rack is a direct unit which functions with no assist at higher vehicle speeds. The ECD receives signals from a speed sensor and, coupled with a steering sensor for torque and rotation, it then calculates the amount of assist and sends a signal to the motor.

The recirculating ball system provides the power assist to the rack. This simple, lightweight system requires no hydraulics and draws no power from the engine.

To ensure reliability, the electrical system for this unit features gold-plated connectors. The steering ratio is 18.6:1.

Forged Alloy Wheels

To further reduce unsprung weight and provide the highest strength possible, the engineers specified forged aluminum alloy wheels. The process is a three-stamp, dual heat process. A billet of forged aluminum alloy is heated in an oil bath and then stamped. This procedure is repeated three times. The wheel is then spun to the final dimensions in a forming roller.

The result is a very light wheel with the strength and impact resistance of a heavier cast aluminum wheel. The rear wheels are 8×16 in. and the front wheels are 6.5×15 in. Compared to cast aluminum, the total weight savings of all four wheels amounts to 6 kg. (13.2lbs.).The spare is cast aluminum, space saver type.

Tires

The goals for the tire chosen for the NSX went beyond the expected goals of excellent dry and wet weather traction and cornering ability. The suspension engineers, working in conjunction with Yokohama Rubber Co., Ltd., sought to produce a tire that would allow the driver to readily “feel” the limits of the tires’ performance. This goal arose from the original concept that the NSX be a car that could easily be driven to the limit. In addition, the tire had to provide good durability, wear resistance, low noise level and good ride quality.

The two-year development period began with computerized simulations for creating the carcass and developing low-noisetread patterns. The actual work of refining the tire to provide superior feel required extensive track testing by professional drivers.

As a result of this computer and track testing, the tires on the NSX are not only different sizes front at rear (205/50ZR15 front, and 225/50ZR16 rear) but they also feature a different tread block configuration and different compounds front and rear.

Called the A022, the tires use a mixture of two compounds, the Tread Compound and the Undertread Compound. The Tread Compound contributes to wet and dry traction while the Undertread Compound contributes to handling stability, high speed stability and predictable reaction to steering input. The ideal “feel,” response and traction for front and rear tires were accomplished by adjusting the ratio of these two basic compounds.

The belt material is a newly developed, highly pliant, small diameter filament which contributes to maintaining the shape of the contact patch under cornering and lane change maneuvers and also contributes to ride quality.

Using new technology recently developed for racing tires, a new sidewall and bead filler material were used in the A022 tires. This produces a slightly harder sidewall which was fine-tuned from tread area to the the bead area and which contributed to the tire’s ability to transmit information about the tire’s limits to the driver.

To ensure high speed durability in excess of the car’s actual top speed potential, a jointless belt cover was specially developed.

During the two-year development period, Yokohama produced and rejected ten separate molds and used more than 6000 test tires in over 100 different formulations of compound and construction before selecting the ideal final specification tire for the NSX.

1991 Acura NSX – Engine

Engine

The design targets for the engine that was to power the Acura NSX were light weight, high power output per liter, high revving capability, smoothness and instantaneous throttle response. Equally important was excellent fuel efficiency in order that the car avoid the U.S. gas guzzler tax.

A number of different engine configurations were considered but the optimum choice was a normally aspirated V6. Turbocharging or supercharging was dismissed because of the inherent boost lag which adversely effects instant throttle response. Compound turbos and superchargers were also discarded because they added a layer of complexity that the project team felt was not part of the NSX’s portfolio. They wanted to keep the NSX as pure and as simple as they could. But could a normally aspirated V6 be made to produce very high power levels and still yield the durability, reliability, and smoothness for which Honda engines have been famous? The answer is obviously yes, but to get there, the engineers had to tap every resource at their disposal and practically re-invent valvetrain technology. The approach they took in developing the engine was fundamental. They felt that by optimizing basic engine technology and coming up with some fresh thinking, all the targets were achievable. In its final state of tune, the engine has among the highest power per liter output of any normally aspirated engine.

Overview

The result is an all-aluminuml 3.0 liter (2977cc), dual overhead cam, four-valve per cylinder, V6 engine which produces 270 hp at 7100 rpm when mated to the manual transmission, and 252 hp at 6600 rpm when mated to the automatic transmission. The torque rating is 210 lbs.-ft. at 5300 rpm for both manual and automatic transmissions. The redline for the manual is 8000 rpm while the automatic is 7500 rpm. Fuel cutoff is 8300 rpm for the manual and 7800 rpm for the automatic. The engine has a bore and stroke of 90 x 78 mm. The compression ratio is 10.2:1.

An exclusive Variable Valve Timing and Lift Electronic Control System (VTEC) has been developed which optimizes volumetric efficiency at both high and low engine speeds.

Engine Block, Cylinder Heads, Crankshaft

To achieve both light weight and durability, the 90 Deg. -V engine block is made of aluminum alloy with cast-in steel cylinder liners. The bore pitch is 100 mm and the deck height 221.5 mm. The crankshaft is a fully counterweighted forged steel unit. The diameter of the crankpins is 50 mm and the main journal diameter is 64 mm.

The cylinder heads are low pressure cast aluminum with a different alloy than the block. This alloy was specially formulated to reduce the possibility of stress cracks. The combustion chamber is a pentroof design with generous squish area to enhance combustion efficiency. The spark plug is centrally located for correct flame propagation and features a platinum tip for improved durability and longer service life. This tip also has a special raised design to improve plug performance and enhance reliability.

Pistons

The pistons are made of a specially formulated aluminum alloy. A molybdenum coating is applied on the piston skirts to help reduce friction and improve efficiency and power. The piston ring thicknesses are 1.2 for the top and middle ring, and 2.8 mm for the oil control ring. These thin but strong rings have been optimized to reduce friction and are very light to reduce ring flutter.

Titanium Connecting Rods

The connecting rods are made of a specially patented titanium alloy. While titanium rods are common in Formula One and other race engines, this is the first application of titanium in a production car. The benefits of lightweight reciprocating parts like con rods and pistons, are many and already well-known. Lighter but very strong parts produce less parasitic power loss thereby making the engine more efficient, improving throttle response, and allowing for sustained high rpm operation without any loss in durability. Compared to a steel rod for the same engine, these titanium rods weigh 190 grams less but are significantly stronger. They can withstand 65 kg.lsq. mm of stress along the longitudinal axis compared to 50 kg.lsq. mm for steel. A chrome nitrite surface treatment on the large end helps to minimize wear.

VTEC

Without question, the Variable Valve Timing and Lift Electronic Control System (VTEC) is a breakthrough in engine technology.It convincingly solves the age-old trade-offs between low end torque and high end power. With VTEC, there’s no need to compromise between one and the other. The heart of the VTEC system is a unique camshaft and rocker arm system. VTEC is installed on both intake and exhaust sides but for purposes of clarity, we’ll restrict the discussion on its operation and benefits to the intake side.

For each cylinder’s set of two intake valves there are three corresponding lobes on the camshaft. The two outboard lobes each have a profile suited for low engine speed operation. Each of these two lobes have a different lift profile to induce a swirl for more complete combustion. One has a total lift of 8.7 mm and the other is 8.3 mm. These two lobes act on rocker arms which in turn act on the intake valves in a conventional manner. The third, or center earn lobe, has a dramatically different profile designed for longer duration and higher lift. Lift on this lobe is 10.2 mm. This lobe profile is designed to optimize breathing and horsepower production at high engine speeds.

This high lift lobe acts on the center rocker arm, and this arm in turn acts on a lost motion spring. The spring is merely there to reduce arm play while VTEC is disengaged.

Besides the center, high lift lobe, what makes this valve train different are two pistons and a stopper pin installed at right angles in the rocker arms. Under high load or high speed operation, the VTEC computer sends a signal to a spool valve which in turn delivers engine oil to the pistons in the rocker arms. Oil pressure causes the pistons to slide inward, locking all three rocker arms together. It takes 4.5kg.lsq.cm oil pressure to overcome the spring pressure and engage VTEC. Once locked together, the rocker arms are then forced into following the profile of the high lift center camlobe. At this point the intake valves have the higher 10.2mmlift and longer duration, a condition which promotes better engine breathing and produces a noticeable increase in power. The cross-over from low lift to high lift occurs in 0.1sec. and is virtually transparent to the driver.

The cam lobe surface material is nickel chrome molybdenum and receives heat treatment, chilling and an oxidation process to ensure proper surface hardening. The high rpm, center lobe has an additional remelting process treatment to further enhance durability.

The two exhaust valves have lift of 7.7and 7.4mm in normal operation and go up to 9.0mm when VTEC is engaged. The timing and duration is also altered when VTEC is engaged. When mated to the automatic transmission, the engine has a different set of lift and duration specifications to tailor the power and torque curve to this transmission.

VTEC Valve Timing for Engine with 5-Speed

| . | Intake | Exhaust | |

| VTEC Disengaged | Valve 1 | Valve 1 | |

| . | Opens | 7.5 Deg. ATDC | 30 Deg. BBDC |

| . | Closes | 25 Deg. ABDC | 7.5 Deg. BTDC |

| . | Lift | 8.7 mm | 7.7 mm |

| . | . | Valve 2 | Valve 2 |

| . | Opens | 12.5Deg. ATDC | 25 Deg. BBDC |

| . | Closes | 25 Deg. ABDC | 7.5 Deg. BTDC |

| . | Lift | 8.3 mm | 7.4 mm |

| . | VTEC Engaged | Both Intake Valves | Both Exhaust Valves |

| . | OPENS | 5 Deg. BTDC | 40 Deg. BBDC |

| . | CLOSES | 45 Deg. ABDC | 5 Deg. ATDC |

| . | LIFT | 10.2 mm | 9.0 mm |

VTEC uses a dedicated CPU which monitors a number of engine parameters and activates the system only when certain thresholds are met. It’s designed to engage between 5800 and 6000 rpm depending on conditions and will not engage under a no load situation. As installed and calibrated in the NSX engine, VTEC adds 20 hp and also provides more torque and a broader torque curve. The earn drive belt is a lightweight, high strength synthetic unit made of woven cloth, rubber and glass fiber with an adhesive between the layers. The belt teeth have a special weave for added strength. To minimize vibration, the earn pulleys have been inertia mass tuned. VTEC is covered by numerous patents and is exclusive to Honda.

Valves

To improve durability and reduce airflow restriction, the valves are made of a special high strength tool steel allowing the valve stem size to be 5.5 mm. Valve adjustment is by conventional screw arrangement because it was found that hydraulic tappets produce too much friction and inhibit high rpm operation. The engine has rev limiter settings of 8000 and 7500 rpm (manual and automatic respectively).The diameter of the intake valves is 35 mm and the exhaust valves are 30 mm in diameter. The intake port diameter is 33 x 55 mm while the exhaust port diameter is 33 x 48 mm.

Variable Volume Induction System

In addition to variable valve timing, the NSX engine also uses a variable volume induction system. This system uses a separate magnesium plenum, located beneath the main intake manifold. This second plenum is separated from the primary manifold by six butterfly valves. These valves open at approximately 4800 rpm and are activated by manifold vacuum. The bores which connect the primary and secondary manifold are 64 mm in diameter. The volume of the primary intake plenum is 4.6 liters while that of the secondary plenum is 2.4 liters. W

hen the butterfly valves are closed, the main intake manifold separates the front and rear bank of cylinders. Under this condition, the chamber creates a resonance effect which improves low and midrange torque. When the valves open, one large chamber is created and ties both banks of cylinders to the same intake plenum. This reduces the resonance effect but creates an inertia ram tuning effect which optimizes high end breathing and provides more horsepower. This system was designed to work in concert with VTEC to improve low end torque. The diameter of the intake runners is 46 mm and the total length of each runner is 325 mm.

Programmed Fuel Injection (PGM-FI)

Programmed sequential port fuel injectionensures that each cylinder receives only the precise amount of fuel necessaryfor the givenload and speed conditions. This system, although similarin concept to the systemfound in the Legend, has been specially tailored to the unique capabilitiesof the Variable Volume Induction system and the VTEC system.

The fuel injection system is controlled by an eight-bit microprocessor which monitors several sensors including throttle angle, crankshaft angle, coolant temperature, intake air temperature, manifold air pressure, ambient air pressure and exhaust gas oxygen content. The system meters fuel at the correct stoichiometric ratio under all operating conditions to provide maximum performance and fuel efficiency.

To ensure adequate fuel delivery even at elevated engine speeds the injection system is rated at 120 liters per hour at maximum operating range and 60 liters per hour at normal operating speeds. Fuel pressure is 3.5 kg./sq. cm +- 0.05.

Air Intake

Air for the engine is delivered by means of an intake duct on the driver’s side, rear quarter panel. To reduce the roar and intake boom commonly associated with this type of intake system, a tuned duct is used to route the intake charge to the manifold cancelling intake noise. The intake duct on the right side of the vehicle is used to cool the engine compartment while a fan directs ambient air to the alternator to keep it cool and maintain optimum charging efficiency. The diameter of this fan is 155 mm.

The air cleaner element has been specially designed to minimize restriction of air flow into the engine.

The volume of the air cleaner housing is 9.7 liters and the surface area of the air cleaner element is 3940 sq. em. The intake air snorkel is 90 x 320 mm.

Direct Ignition System

To ensure a hot, stable spark at high rpm operation, the single coil ignition system has been superseded by a coil mounted atop each spark plug, a design similar to that used in the Honda Formula One car. This system ensures a stable spark up to 8000 rpm. A sensor mounted behind one of the camshafts is the trigger for spark plug ignition. Also, specially designed platinum-tipped spark plugs help increase ignition energy and enhance plug life.

Oil System

To supply the necessary amount of oil at high engine speeds, a new high-volume recirculating oil pump has been developed. Oil pan scavenging has been improved by use of a oil baffle in the pan. The NSX can maintain a sustained 0.8g lateral load without oil starvation and can spike up to 1.2g without starving for oil. The flow capacity of this pump is 68 liters per minute at 6000 rpm and operates at 6.8kg./sq cm pressure. Oil pressure is monitored by a gauge in the instrument panel. The recommended engine oil is lOW-30SG.To maintain appropriate oil temperatures, a liquid cooled oil cooler has been designed. It’s located at the base of the oil filter mounting boss. The oil pan capacity is 4.3 liters while total engine oil capacity is 6.3 liters.

Cooling System

The goal of the cooling system was to provide maximum cooling efficiency at high speeds, medium speeds and at idle even in the harshest climate. The radiator core is made of aluminum and the header tank of a special high-strength nylon. The flow capacity of the belt-driven water pump is 150 liters per minute at 6000 rpm. The fins of the radiator are 2.5 rom thick and they have a 2 Deg. pitch for maximum cooling efficiency. The radiator fan is 320 rom in diameter. The entire cooling system is rated at 47,100K Cal/hour.

The radiator fins, tubes and pipes carrying coolant from the radiator to the engine are all made from aluminum. Development work on the cooling system was conducted in the Australian desert in more than 100 Deg. E ambient temperature. Testing was conducted with the air conditioning unit operating at all times. Some of the targets included repeated runs at 140 mph on level ground and up a 5.6% slope, and sudden stops from high speeds followed by an extended hot soak at idle.

The intake duct on the right side of the vehicle is used to cool the engine compartment while a fan directs ambient air to the alternator to keep it cool and maintain optimum charging efficiency. The diameter of this fan is 155 rom.

Exhaust System

The dual exhaust system has been developed to produce equally low exhaust back pressure on both sides. The exhaust headers are a unique cast iron composition while the rest of the system is stainless steel for improved corrosion protection. The system uses dual catalytic converters with dimensions of 81.3x 144.8x 95mm. The volume of each catalytic converter is 0.95 liter.

The exhaust note of an exotic is an important part of its personality. In a sense, it’s the voice with which it addresses the world. In tuning the exhaust note the engineers wanted a sound that reflected the car’s high level of technical competence and one that clearly set it apart as the new-generation exotic. The sound had to be aggressive and powerful but above all it had to be a clean high-register note – more evocative of a Formula One car than a large displacement street engine which typically has a low, guttural sound. At steady speed, the system is designed to be un-intrusive. But it makes its presence known under acceleration.

Manual Transmission

The goals for the manual transmission were to create a transaxle package matched to the high power and torque of the NSX engine and to provide the driver with a short throw gear change, smooth engagement, and a light, progressive clutch.

The transaxle features a double-cone synchronizer in second gear and a synchronized reverse gear as well. Also, gear noise in all forward gears has been reduced and the typical whine found in many reverse gears has been eliminated by a combination of refinements including design of the gear teeth and adjusting backlash.

These goals were achieved by developing a number of refinements. These design details have produced significant improvements and contributed substantially to the feel and precision of the manual transmission. The shift change load is significantly lighter than the leading competitors. The shift throw is 40 mm, which compares well to the 60 to 70 mm of most exotics. The shifter uses a large diameter cable design to the trans axle which provides excellent shift feel and precision.

Additionally, oil agitation and foaming has been reduced significantly by developing a forced lubrication system driven by a trochoid oil pump. The pump is located in the transmission and is powered by a spur gear.

Gear ratios in the manual transmission are below;

| 1st | 3.071:1 |

| 2nd | 1.727:1 |

| 3rd | 1.230:1 |

| 4th | 0.967:1 |

| 5th | 0.771:1 |

| Reverse | 3.186:1 |

| Final Drive | 4.062:1 |

The overall weight of the manual transmission is 76.7 kg. including the clutch.

Twin Disc Clutch

As the major interface component between the engine and the rest of the drivetrain, the NSX clutch design received considerable attention. The first design priority was that it be able to withstand the power and torque of the engine. Also, it had to have a short stroke, engage smoothly, offer low effort in order that it not become tiring in city driving and it had to be light and compact.

To meet all these requirements, the engineers designed a hydraulically activated, self-adjusting, pull-type clutch with a twin disc configuration. The twin disc design is a smaller diameter than a single disc clutch and reduces the rotational mass of the unit. The smaller diameter allows the engine to rev more quickly. For enhanced durability, the second pressure plate is ventilated to dissipate heat build-up. An aluminum pressure plate housing is used to reduce overall weight.

This unit requires only a 13 kg pedal effort, despite the high horsepower and torque ofthe NSX engine. Competitors have pedal efforts in the range of 14 to 19 kg. The stroke is only 130 mm. The clutch pedal stroke measured on most of the competitors in this class ranges between 135 and 155 mm. This unit also offers a linear and very progressive take-up to provide smooth clutch engagement and prevent the jarring all-in or all-out clutch engagement typical in many high horsepower cars. This is accomplished by having the first plate engage and then the second in a progressive manner.

Automatic Transmission

For drivers who choose the 4-speed automatic transmission, the engineers wanted to provide them with the same sporty feel as the manual. Under maximum acceleration, this 4-speed transmission holds each gear close to the redline before upshifting. This transmission allows the driver to manually select each gear. A solenoid is used in place of a throttle cable to activate the kickdown. And, to enhance smoothness between upshifts and downshifts, an ignition retard control system is used to momentarily reduce engine output.

Under cold, fast idle conditions with the transmissionin “Drive”, the transmission automatically engages 2nd gear to reduce forward creep, but automatically selects 1st gear when movingoff. The automatic is also equipped with a programmed lockup torque converter to improve fuel economy and reduce slippage. Lock-up is available in third and fourth gears and, unlike other automatic transmissions, it occurs in four increments, rather than one abrupt transition, to provide smooth operation. The transmission is unique in that it maintains lock-upwhile the car is decelerating. To ensure maximum reliability 2nd, 3rd, and top gear are made of a high strength material and a transmission fluid cooler is fitted as an integral part of the torque converter case.

The gear ratios are:

| 1st | 2.611:1 |

| 2nd | 1.551:1 |

| 3rd | 1.025:1 |

| 4th | 0.684:1 |

| Reverse | 1.909:1 |

| Final Drive | 4.428:1 |

The overall weight of the automatic transmissionis 104Kg.

Torque Control Differential

The torque control differential is designed to help maintain traction when driving over split friction surface conditions and maintain vehicle stability at speed in crosswinds. It employs a multi-plate clutch and planetary gearset design. Like many conventional LSD (Limited Slip Differential) systems, this unit resists the rotational difference between the rear wheels and attempts to maintain the same rate of rotation at both wheels. But unlike most units, the amount of additional torque resisting the rotational difference is limited to 16 kg-m. This reduces understeer by not trying to keep the car from going towards the direction in which it is being steered. In a cornering situation, too much torque transfer to the inside rear wheel tends to oppose the turning moment from the front wheels, thereby increasing understeer.

If the NSX should be disturbed from its intended direction in a crosswind, the differential will detect the rotational difference between the two rear wheels and transfer torque to the slower rotating wheel. This has the effect of helping to keep the car on the desired path.

Compared to both conventional open differentials or limited slip differentials, straight line tracking is improved, especially in cross winds. On a split friction road surface, the acceleration time was reduced compared to a conventional open differential.

Flat Roller Constant Velocity Joints

To manage the high power output, reduce vibration, increase the service life of the driveshaft, and minimize harshness a new, flat roller CV joint was developed for the NSX. This new design allows for a larger amount of lateral slide motion (57 mm vs. 22 mm compared to the average in this class) which reduces the possibility of binding and excessive vibration under maximum vertical loads. It’s also smaller in overall height (92 mm vs. 108 mm for the competition).

Traction Control System (TCS)

One goal of the Traction Control System (TCS) is to minimize rear wheelspin on slippery or uneven road conditions. Yet unlike some other traction control systems, this Honda R&D development was created as a high performance system that functions over a wide range of speeds and cornering situations rather than simply a low-speed traction enhancing device. The key to this is creating a system that could differentiate between low speed, poor traction conditions and high speed cornering and modulate the wheelspin accordingly.

TCS uses the wheel speed sensors of the Anti-Lock Braking system to detect the rotational differences between the two front wheels. Using this information, plus vehicle speed and changes in steering wheel angle from a steering wheel angle sensor, it estimates the yaw rate and the cornering force (or lack of it) acting on the car. It compares this information to a map stored in the TCS central processing unit and determines whether or not the car is cornering hard on dry pavement or is tending to spin its wheel( s) on a slippery surface.

If the computer determines that the surface is slippery, CPU signals are sent to the fuel injection system and decrease the amount of fuel delivered to the engine. A signal is also sent to a step motor attached to the throttle plate which incrementally closes the throttle. This has the effect of reducing engine power, thereby reducing power to the rear wheels, and suppressing wheelspin. The system maps are sophisticated enough that TCS can determine the difference between a road which is dry,wet or icy.As a further refinement, a vibration sensor is installed which determines if the vehicle is travelling on a rough road. In this scenario, it suppressesor allows wheelspin in accordance with the rapidly changing conditions. The elapsed time between detecting wheelspin and taking the appropriate action is 0.3sec. The driver can elect to disengage TCS by a switch located on the instrument panel.

1991 Acura NSX – Interior

Security System

A sophisticated alarm system is standard equipment on the NSX. Sensors are mounted in the doors, engine hatch, trunk, hood, battery cable, radio and ignition switch. If an attempt is made to open a door or any hatch, or hot-wire the ignition, the alarm will trigger. When triggered, the horn sounds and the flashers are energized and the ignition system is disabled. The system arms passively 15 seconds after the doors are locked and is disarmed when a door is unlocked with the key.

Seating Position and Visibility

A low seating position contributes to a low center of gravity and helps to reduce the frontal area for improved aerodynamics. It’s also an essential part of an exotic car’s personality. Properly locating the hip-point is the first step in creating the interior space and establishing the relationships between the driver, instrument panel, steering wheel, pedals and other major controls.

The H-point in the NSX was located as low as possible and situated nearly at the mid-point of the wheelbase. Ordinarily, a low hip-point would impart to the driver the feeling of being buried in the interior and create a claustrophobic feeling. To avoid this, the body engineers created a very low cowl section which allowed them to lower the height of the dash and instrument panel. This low cowl section was made possible by efficiently packaging the front suspension and by using a smaller, 15 in. wheel at the front, compared to a 16 in. wheel at the rear.

Major interior dimensions are as follows:

| Head Room | 36.3in. (921mm) |

| Leg Room | 44.3in. (1126mm) |

| Hip Room | 53.8in. (1366mm) |

| Shoulder Room | 52.5in. (1334mm) |

The 15 in. wheel also allowed a wider footbox and made possible a natural relationship between steering wheel, pedals and seat. Unlike some exotics, the pedals didn’t need to be severely shifted inward to clear the wheel housing.

The low cowl also improved vertical visibility. Forward visibility is 23.5 Deg. and rear visibility is 15.7 Deg. There is an additional 2.40 Deg. visibility under the rear spoiler. The driver side horizontal visibility out the left side is 103.5 Deg. and out the right side it’s 44.4 Deg. Front visibility is 84.2 Deg. and rear visibility is 79.7 Deg. Total all-around visibility is 311.8 Deg.

To maximize head room the headliner has been scalloped in the area above each occupants’ head. The scallop also amplifies the interior “helmet” concept.

Instrument Panel and Dash

In designing the instrument panel, the approach was one of simplicity. Since the main mission of the instruments is to relay information in as clear and quick a manner as possible, the designers rejected anything that might conceivably be perceived as gimmicky. Instead, they opted for a traditional analog execution.

The instrument faces are round with white numerals on a black background. The instrument panel is dominated by the tachometer on the left and the speedometer on the right. To the left of the tach are the smaller water temperature and oil pressure gauges. To the right of the speedometer are the fuel gauge and voltmeter.

Nestled between the tach and speedo is a pictogram indicator for door and hatch ajar warning.

All the major controls are clustered around the steering wheel column to make them easy to reach. The turn signal stalk is to the left of the wheel. This stalk houses the headlight switch and the cruise control function. The wiper/washerfunctions are housed on a stalk to the right of the wheel. Also on the right, mounted on a separate pod are the rear defogger and hazard switch.

The upholstery covering the dash is a newly developed, hand-crafted 5-layer process. To enhance durability, the dash upholstery material is a specially formulated synthetic which is resistant to sun fading and deterioration due to temperature extremes. The dash covering is hand-stitched and hand-formed and is designed to impart a soft, high-quality feel and look. The stitching process is known as a partial single stitch and has a 4.5 mm thread pitch to match the stitching of the seats.

Steering Wheel/ Supplemental Restraint System (SRS)

The leather-wrapped steering wheel is a three-spoke design with a thick rim to provide more surface area for the driver’s hands. It measures 365 mm (14 in.) in diameter. The wheel features a tilt and telescopic adjustment function.

The Supplemental Restraint System (SRS) is mounted in the steering wheel hub. It uses a new silicone material for the bag. This thinner, but equally strong material, allows the bag to be folded into the smaller space of the new wheel hub. Bag triggering is accomplished by means of two impact sensors mounted at the base of the frame rails on the front bulkhead and one sensor inside the car. In order for the bag to deploy, the sensor in the interior must “agree” with one of the two sensors on the bulkhead that an impact has occurred. All SRS electrical connectors are gold-plated in order to enhance conductivity and provide optimum corrosion protection.

In addition to the energy absorbing steering column, the steering wheel spokes are designed to deform and bend backwards toward the dash to absorb energy from impact providing the driver with an extra measure of protection.

Leather-Trimmed Uphostelry and Monoform Seat Design

Leather was a natural choice for the seat trim material and perfectly in synch with the nature of an exotic. The seat upholstery is hand-stitched and hand-fitted to ensure quality craftsmanship and durability. In keeping with the concept of light weight, the seat frame is made of stamped aluminum, the first for a production car. As an indication of lightweight, simplified design, the NSX seat has about 1/3 fewer parts compared to a typical power seat. It’s provided with a power-operated fore/aft and recline adjustment and features deep bolsters for the seat bottom and the lower back area. Different foam densities are used for the bottom and back due to the different load conditions on each area. The side bolsters use a high density foam for more rigid support, while the seat bottom and seat back foam material is of a lighter density. The seat back has a split pad design in order to reduce the tension on the seat surface.

The seat rails are aluminum extrusions and the seat belt anchor is attached to the seat in order to facilitate belt attachment regardless of the position of the seat. All the seatbelt components have a lifetime guarantee.

Automotive Climate Control System

A compact climate control system has been developed specifically for the NSX. Unlike most climate controls systems which are mounted transversely, the heating and cooling components of this system are installed longitudinally in the car in order to improve knee- and legroom. This is an optimum layout for a mid-engine car. The system provides the same cooling and heating capacity as a four-door sedan but it’s 30% smaller in overall size. It features a patented sliding damper door which takes up less room than a conventional flap type damper door. Additionally, this system doesn’t use a traditional single condenser mounted behind the radiator. Instead, two condensers are used. One is mounted inside each of the front fenders with each condenser having its own air duct. The exhaust air from the condensers is routed by vents to the front portion of the wheel well inner liner and then escapes out the wheel wells. This arrangement yields better efficiency than a single condenser design.

This is a fully automatic system but the automatic function can be overridden and the system can be used in a fully manual mode.

The climate control function panel is located above the sound system control panel on the center console and has been placed in an ideal line of sight and within easy reach of the driver. The controls can be operated without diverting the driver’s attention from the road.

Acura Bose® Sound System

Bose engineers became involved with the NSX sound system at the final stage of interior design. This premium sound system features four speakers – two mid-range speakers in each door, a subwoofer in the passenger side footwell, and a midrange/tweeter mounted on the rear bulkhead between the seats.

This system was designed and calibrated specifically for the unique acoustics and resonances of the NSX body and interior structure and provides the highest quality imaging and spatial dynamics for both the driver and the passenger. The speakers are enclosed in specially designed ABS plastic housings. These housings are acoustically tuned and each has a built-in switching amplifier module.

In most systems, the speakers are placed high so that the sound is beamed directly at the listener. The problem with this approach is that the listener is positioned much closer to the nearest speaker than to the speaker on the other side of the car, so that the near speaker will drown out the far one. The net result is a performance that sounds like it’s being played in mono rather than stereo.

The speakers in the NSX are mounted low and forward in the front doors to position them farther from the listeners. This placement minimizes the relative differencein distance between each speaker and the listeners’ ears and reduces the difference in each speakers’ sound intensity. As a result, the listeners will experience a wide open, spacious sound, the type one would hear in a live performance.

The Acura/Bose music system’s speakers are precisely aimed so that the pressure wave of the speaker closest to each occupant doesn’t overpower the pressure wave from the speaker which is furthest away. This produces a balanced sound from each speaker and the net result is true stereo performance.

The AM/FMstereo cassette features Dolby and Dynamic Noise Reduction. The Auto Preset function will automatically lock on eight strong AM and eight strong FM stations and store them into the preset selector buttons. A computer controlled diversity antenna system is utilized to improve FM reception. It uses two antennas. One is laminated into the rear glassand the other is a retractable mast antenna mounted in the fender. The computer determines which antenna is receiving the best signal and instantly switches between the two for the best reception. A six-disc CD changer installed in the trunk is available as an option. The CD control functions are built into the radio control panel.

Luggage Space

The NSX offers 154 liters of rear luggage capacity, enough to accommodate two golf bags. Optional fitted leather luggage is available as an accessory item.

Jack and Air Compressor

The jack and air compressor are located in a recessed compartment under the trunk carpeting. The jack, instead of being made of stamped steel is a machined aluminum unit designed for light weight. The air compressor, which plugs into the cigarette lighter, is used to inflate the space-saver spare which is mounted in the front compartment.

Security System

A sophisticated alarm system is standard equipment on the NSX. Sensors are mounted in the doors, engine hatch, trunk, hood, battery cable, radio and ignition switch. If an attempt is made to open a door or any hatch, or hot-wire the ignition, the alarm will trigger. When triggered, the horn sounds and the flashers are energized and the ignition system is disabled. The system arms passively 15 seconds after the doors are locked and is disarmed when a door is unlocked with the key.

1991 Acura NSX – Body

Design

Like every mechanical aspect of the NSX, the exterior styling had to embody the Honda spirit. Additionally, it had to visually transmit the car’s performance capabilities, high technology aspirations and a refined but aggressive nature. From every angle the car had to display a lean, muscular appearance. From the front and rear, the designers felt it crucial that it have a wide, solid stance. These are categorized as the intangible goals-the purely emotional responses to the car’s shape. But before settling on the final design,a number of concrete goals were also established.

Overview

The basic theme of the the NSX is that of a long-tail,cabin forward design. Locating the visual mass of the greenhouse far forward on the body not only accomplishes the goal of giving the NSXa sleek, aggressive look, it also contributes to the purely functional aspects of the car. The forward cabin location optimizes visibility while the long-tail design enhances high speed directional stability.The long tail also provides adequate space to package the drivetrain and trunk. A wide front and rear track complemented visually with sculptured front and rear fenders, give the NSX a muscular look.

Function and Form

One prime consideration was excellent all-around visibility. Poor rear and rear-three quarter visibility have traditionally been a hallmark of most exotics and the prevailing attitude was that lack of rear visibility is the inevitable price one pays for the advantages of a midship engine placement. Honda saw this shortcoming as unacceptable. Visibility out the front is, obviously, an even greater concern and the designers saw a low cowl height as a key element in the final shape of the NSX.

Good aerodynamics was also an important consideration for high speed stability,low wind noise, and improved fuel economy.Finally, the exterior designers had to provide an envelope large enough to accommodate not just all the mechanical components, but provide a roomy trunk, and ample interior space for the driver and passenger.Furthermore, the space for occupantshad to be properly proportioned and correctly oriented. They wanted to avoid at all coststhe uncomfortable offset pedal and steering wheel arrangement common to many exotics.The pedals, wheel, and seat had to be located in a way that was ergonomically correct and one that felt “natural” to the driver. While this might be considered a task for the interior designers,it’s patently evident that too narrow an exterior front section, would make the interior designers’ job impossible.

The task of the exterior designers was to juggle all these elements, some of which were in direct conflict, and create a harmonious, organic shape.

Thematically, the F16 came into play here just as it did in establishing the conceptual goals of the NSX. In the F16, and other high performance craft such as Unlimited Hydroplanes, single seat race cars, etc., the control center, or cockpit, is located far forward on the body, well in front of the power unit. This design is a natural outgrowth of the function of the craft. The driver, or pilot, needs to see as much of his environment as possible-whether slicing through the sky at Mach II or aiming for an apex at 150 mph.

The cabin-forwardtheme seemed proper and natural for the NSX. It performed the aesthetic function of makingthe car look purposeful and powerful and evoked the image of a high performance craft. It alsoperformed the practical functions of putting the landscape right in the driver’slap where it belongs and allowingthe packaging space for the engine, drivetrain and fuel tank.

A natural adjunct of the cabin forward arrangement is the shape of the greenhouse proper. A number of themes were explored and the shape that emerged as the most graceful and flowing was the evocation of a fighter’s canopy. This particular shape lent itself naturally into a sloping hood and fender line, which, when coupled to the lowcowl height offered the bold look and forward visibility benefit the designers were pursuing. The canopy-shaped greenhouse also provides excellent rear and rear three-quarter visibility.

Another theme they explored was that of a jet fighter pilot’s helmet. They wanted to give the driver the impression that he was actually out in the windstream. To execute this ambiance for the driver required merging exterior styling and interior details which will be detailed later in the Ergonomics discussion.

Once this canopy theme was established, the designers explored a number of body themes in order to find a shape that best telegraphed the car’s personality. They felt that a clean, sweeping line from nose to tail, one that rose gradually to meet the rear spoiler was in keeping with the car’s personality and its philosophical reason for being.

The final form is a successful integration of all the various elements with which the designers had been grappling. Firstly, to emphasize the fighter canopy look, the A and B-pillars and the roof would not be painted in body colors, but rather be painted black. This marks a clear separation between the body and the greenhouse creating the impression of a light and airy upper and a strong, aggressive lower body. Another visual cue that further enhances the separation between greenhouse and body is the design of the door handles which have been fitted to the leading edge of the B-pillar and also painted black. This detail creates a clean door panel and enhances the uninterrupted visual flow of the body line. The idea was not to trip up or catch the eye as it swept from front to rear.

Wheel openings were designed to be just large enough to accommodate the wheel and tire practically.This minimizes the clearance between body and wheel which maintains a tight, uncluttered look and also helps airflow management. The wheel designitself is simpleand purposeful. Five fairlybroad spokes with clean radiused surfaces enhance the sporty image. From a straight-onfront or rear view,the wheels are practicallyon the same plane as the body sides and contribute to the wide stance and aggressive look.

At the rear the design of the spoiler was integrated into the quarter panels. The panels rise sharply at a point just past the end of the rear wheels and fold into a single sweepingline to merge into the rear spoiler.The center high mounted stop light was designedinto the trailingedge of the spoiler in order to maintain a unified, integrated look.

The most visually striking aspect of the NSX is the long-tail design. This gives the car a long, lean look. The long tail and integral spoiler contribute significantlyto high speed directional stability.The long tail alsoprovides ample space to package the mechanical components.

The area below the rear bumper is evocative of the Formula One underbody tunnels which help to evacuate air fromunder the car at speed and help to create downforce.

The leading edges of the functional side air intakes were brought far forward on the body all the way to the leading edges of the doors. This detail emphasizes the fact that this is a mid-engine car and helps contribute to the overall long look of the body.

At the front, the turn signal/parking light units were designed to wrap around to the side of the fenders. They terminate on the same vertical plane as the inside edge of the headlight covers. Also, to help tie the retractable lights and the parking lights visually, the parking light opening has a sharp bevel design, similar to the bevel designed into the lower leading edge of the headlight opening. This bevel theme is also echoed in the large hood notch which serves to increase the driver’s lower sight line and to emphasize the strong, muscular appearance of the fenders.

Three air intake openings were designed into the front cap. The large central opening for radiator cooling is divided horizontally by a single, thin airfoil section which visually has the effect of reducing the size of the opening maintaining the proportions of the opening relative to the front end. The openings on either side are designed to terminate on the same plane as the inside edge of the headlight cover and the inside edge of the parking light unit. This again visually ties all three elements together. Below the front bumper, a black chin spoiler was designed for aerodynamic improvements.

Aerodynamics

Aerodynamic development began at the same time final surface development was underway. Aero testing was first conducted using one-fifthscale models. This was done in an effort to validate overall shape and conceptual themes. Final testing was conducted with full-sizecars at the JAR! (Japan Automotive Research Institute) wind tunnel in Japan and at the DNWwindtunnel in the Netherlands with all final specificationequipment installed (European or U.S. speclicenseplates, lights, air conditioning condensers etc.).

The initial target was to refine the surface detail in order to produce a Cd of less than 0.33, a Cl near zero, and a coefficient of yaw moment of 0.25 at a 30 Deg. angle of attack relative to the car’s centerline. As a high performance car, the aerodynamicists perceived lift and yaw moment just as crucial as a low Cd. The ultimate goal was to achieve a balance of Drag, Lift and Yaw forces and create a car which was stable at speeds under a variety of wind conditions.

From the very beginning of aerodynamic testing it was found that the cabin forward arrangement waswell suited for overall aerodynamicefficiency. The long tail, short front designwas found to be ideal for enhancinghigh speed directional stability and maintaininglaminar airflow.

Starting with this aerodynamically sound envelope the engineers set about refining and optimizing the surface. To improve downforce at the rear, the design of the integral spoiler was developed to enhance high speed stability, reduce the yaw moment, achieve neutral lift and eliminate turbulence.

During wind tunnel development, seven crucial areas were optimized to create the balance of aerodynamic forces the engineers had targeted. These were the taper angle of the front end, the front end section height and shape, the area under the front bumper, the taper angle of the rear section, the angle of the rear glass,the length of the tail and rear overhang and the height and angle of attack of the rear spoiler.

Part of the original designof the car was to provide ample leg room and eliminate the offset drivingposition mentioned earlier. To do this required a front end which doesn’t taper to a sharplypointed nose, but rather a nose whose width remains fairlyconstant from A-pillar to bumper. An empirical evaluation might lead one to the conclusion that this would impact adversely on good air penetration at speed. Interestingly enough, the wind tunnel indicated quite the contrary. Despite the fairly wide front end, for an exotic, the Cd didn’t suffer at all from this condition. As a result, the NSXis able to provide the driver and passenger with natural seating positions and still maintain good aerodynamic characteristics. The area under the hood has been left open at the bottom in order to provide maximum cooling air flow for the radiator. Ambient air is ducted through the grille, passes through the radiator and is then allowed to escape underneath the car. The air intake ducts for the air conditioning condensers, mounted low inside the front fenders, were optimized for maximum air flow and minimum aerodynamic drag. The under body area was also smoothed for better air flow and reduced turbulence. The bottom of the central tunnel has been enclosed with a plastic cover and many components have been tucked up out of the airstream. To further improve laminar airflow and reduce wind noise, the NSX features virtually flush mounted glass with only a 4mm distance between the glass and surrounding frame. The net result of the aerodynamic development project is a final Cl of 0.05, a Cd of 0.32, a yaw moment of 0.24 @30 Deg., and CdxA of 0.57. The frontal area measures a compact 1.78 square meters.

Structure

A rigid structure is of paramount importance in a performance car. High rigidity provides a stable platform for proper suspension geometry and alignment, and it makes possible a tight, rattle free interior. A structure that flexes under torsional or bending loads will upset the suspension geometry causing unwanted toe-change, steering deflection and a host of handling problems.

Additionally, central to the goal of performance is a favorable power to weight ratio. It’s obvious that a heavy car needs a lot of power to achieve high levels of performance. Conversely, a very light car can achieve the same performance levels with less horsepower. With that goal in mind, several research projects were launched.

This project examined virtually every material to determine its feasibility for a light weight unit-body chassis. The materials examined included steel, aluminum, carbon fiber, sheet molded plastic, fiberglass,and many other forms of plastic. They were examined for strength, rigifty, weight, flammability, formability, cost and of course, availability in the quantities necessary for production.

The result of this investigation lead the project team to the conclusion that aluminum was the ideal material for this application.

Although aluminum is roughly one-third the weight of steel, it’s less rigid. It also costs 5 to 6 times more than steel.Thus the major challenge was how to exploit the weight advantage of aluminum while overcoming all the other disadvantages.

Aluminum, for instance, isn’t as malleable as steel and is therefore much more difficult to form into the hundrelds of complex shapes necessary to create a car’s structure. In a stamping operation, aluminum tends to tear, while steel bends and forms more easily into shape. Also, the surface finish of aluminum stampings is rougher than steel. If paint is applied to this rough surface, it produces less than satisfactory results. While this cosmetic consideration is irrelevant when dealing with the under-structure, it becomes extremely important when stamping the exterior body panels. The solution was found by using specially polished dies. Although these dies required the highest quality control procedures they provided the flawless surface finish the engineers had targeted for the Acura NSX.